Page 3 - Design Criteria.qxd

SEO Version

SECTION I

Gasket Selection

Gaskets can be classified into three categories: soft cut, semi-metallic and metallic types.

The physical properties and performance of a gasket will vary extensively, depending on the type of gasket selected and the

materials from which it is manufactured.

Physical properties are important factors when considering gasket design and the primary selection of a gasket type is based on

the following:

• Temperature of the media to be contained

• Pressure of the media to be contained

• Corrosive nature of the application

• Criticality of the application

4

®

Welcome to the Next Generation of Sealing Technology

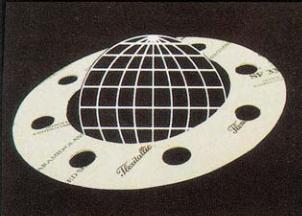

Sheet materials are used in low to medium pressure services. With careful selection these

gaskets are not only suitable for general service but also for extreme chemical services and

temperatures.

Types: Non-asbestos Fiber Sheets, PTFE, Biaxially Orientated Reinforced PTFE, Graphite,

Thermiculite, Insulating Gaskets.

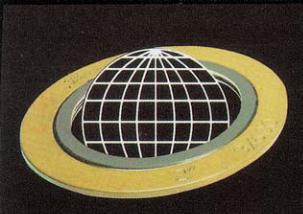

These are composite gaskets consisting of both metallic and non-metallic materials. The

metal provides the strength and the resilience of the gasket and the non-metallic component

provides the conformable sealing material. These gaskets are suitable for low and high pres-

sure and temperature applications. A wide range of materials is available.

Types: Spiral Wound Gaskets, Flexpro Gaskets (covered serrated metal core), Metal

Jacketed Gaskets, MRG’s (metal reinforced gaskets).

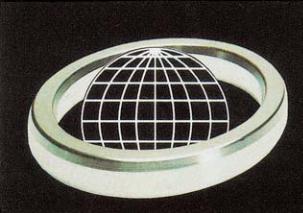

These gaskets can be fabricated in a variety of shapes and sizes recommended for use in high

pressure/temperature applications. Except for weld ring gaskets, high loads are required to

seat metallic gaskets, as they rely on the deformation or coining of the material into the

flange surfaces.

Types: Ring Type Joints, Lens Rings, Weld Rings, Solid Metal Gaskets.

Soft Cut

Semi-metallic

Metallic

Powered by FlippingBook Publisher