Page 53 - GarlockFluidSealing2010

SEO Version

B-21

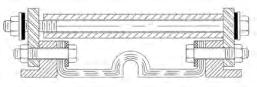

Expansion Joint Components

Tube

¦

Synthetic or natural rubber forms seamless, leak-

proof lining

¦

Extends fully through bore to outer fange edge

¦

Common materials include chlorobutyl, neoprene,

natural rubber, EPDM, Viton* and Hypalon*

Body or Carcass

¦

When wrapped or plied, reinforcements provide sup-

port and fexibility between tube and cover

¦

Fabric reinforcement: polyester or other suitable

fabrics impregnated with specifed elastomers

¦

Metal reinforcement: bonded rectangular steel rings

exclusive to Garlock, or continuous strands of wire

and round steel body rings

¦

Metal reinforcement rings provide longer service life,

extra safety protection, and extra rigidity, allowing

higher pressure ratings

Cover

¦

Homogeneous layer of synthetic or natural rubber

¦

Chlorobutyl is standard; other elastomers available

to meet your specifc applications

¦

Rubber or other weather-resistant coating protects

carcass from corrosion or damage

Metal Retaining Rings

¦

Must be used in all applications; provides metal sur-

face to distribute bolting pressure equally, prevent-

ing fange damage during bolt tightening

¦

Install behind and against inner face of each fange

¦

Standard material: mild steel with corrosion-resistant

coating; galvanized or stainless steel also available

Metal Flow Liners

¦

Extends service life by providing protection from

abrasive materials or solids, especially in high veloc-

ity applications

¦

Flanged at one end, installed at the head of the fow,

tapered to a 5° angle, allows lateral defection

¦

Liner fange thickness: 10 gauge

Liner body thickness: 12 gauge

¦

Available in 304/316 stainless steel; also: titanium,

Hastelloy C**

¦

Special metal liner confgurations also available for

reducing or multiple arch design. Contact Garlock.

Metal Flow Liner Installation

Control Units

¦

Recommended on most applications to pre-vent

damage due to excessive pipe movement

¦

Consists of two or more tie rods connected between

fanges

¦

Triangular end plate has two holes for bolting plate

securely to fange, and one hole to accommodate

plate connecting tie rod

¦

Rubber washer between plate and rod substantially

reduces both noise and vibration

¦

Installing pipe sleeves over tie rods provides addi-

tional protection against overcompression damage

¦

NOT designed to replace pipeline anchoring

Control Unit Installation

Retaining

Ring

Expansion

Joint

Pipe

Flange Control

Unit

Assembly

Optimal

Compression

Sleeve

Powered by FlippingBook Publisher