Page 16 - ConveyorBeltMaintenanceManual2010

SEO Version

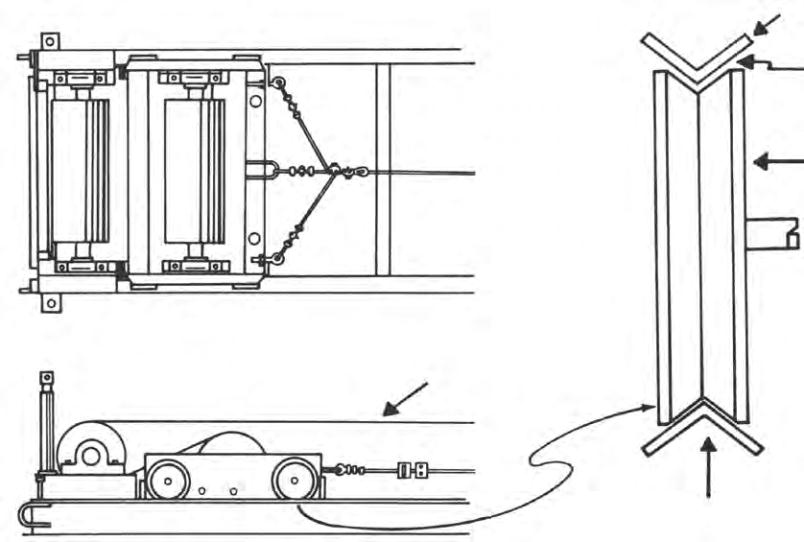

A horizontal take-up carriage (Fig. 14) is subject to misalignment due to loose track gauge, fouled rails, or even jumping off

the track. V-shaped rails will hold the gauge tight and, with the apex upward, are self-cleaning. Hold-down rails or hooks

extending under the flange of the track structure will prevent jumping off the track.

With the empty belt trained satisfactorily, good operation with load is usually ensured. Disturbances that appear with load are

usually due to off-center loading or to accumulation of material from the load on snub pulleys and return idlers.

When equipment is known to be properly aligned, training action should be taken slowly--that is, in small steps,

because the belt requires some time to respond to corrective measures. It should begin at some point preceding the

location where runoff occurs, and gradually proceed forward in the direction of belt travel, until the runoff condition

has been corrected. Under some conditions of operation where the conveyor is not level, is extremely short or is too

wide to be affected by permissible crowning, belts with a special guide strip have been used. This V-guide strip runs

loosely in grooved pulley and idler rolls. Guide strips are not recommended nor are they necessary for the long

conveyors normally encountered in industrial use.

Top View

Side View

Belt

V-Shaped Hold-Down Rail

Operating Clearance

Carriage Wheel

V-Shaped

Main Rail

Fig. 14

Sample Horizontal Take-Up Carriage

14

INSTALLATION, MAINTENANCE & TROUBLESHOOTING GUIDE

i n s t a l l a t i o n

Powered by FlippingBook Publisher