Page 21 - ConveyorBeltMaintenanceManual2010

SEO Version

19

INSTALLATION, MAINTENANCE & TROUBLESHOOTING GUIDE

i n s t a l l a t i o n

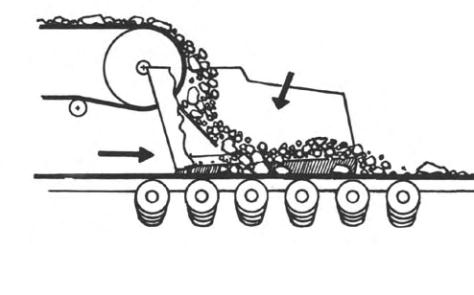

Impact of material being loaded on the belt is often the cause of severe cuts and gouges. The degree of impact can be

lessened to some extent by providing a cushion in the form of rubber covered disc type or semi-pneumatic idlers, which also

tend to prevent material from crowding under the skirt boards at the instant of impact (Fig. 26).

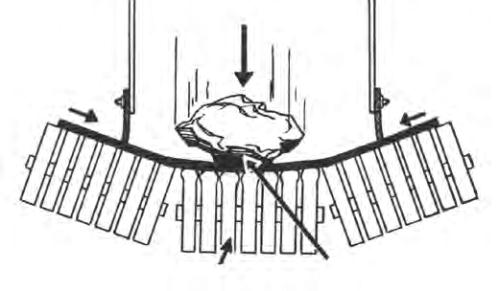

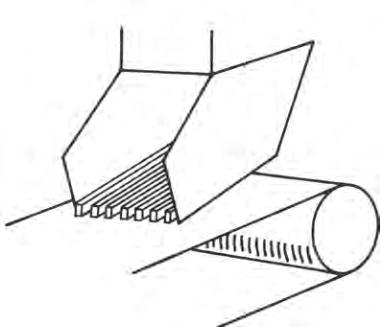

The use of a “Grizzly,” a slightly fanned row of bars, at the bottom of the transfer chute reduces wear on the belt. It distributes

the impact of large lumps by allowing the fines to fall onto the belt first to act as a cushion. The fan shape of the “Grizzly” in

the direction of travel prevents jamming of the lumps (Fig. 27).

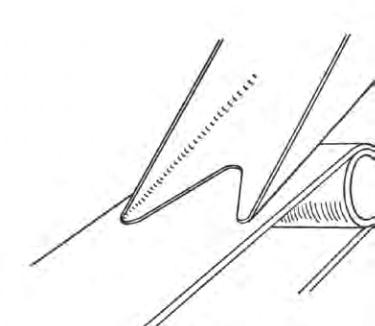

A “V-slot” cut in the bottom of the chute is another very satisfactory method of allowing fines to fall on the belt before the lumps

and thereby reducing belt wear at this point (Fig. 28).

Fig. 27

Grizzly Chute

Fig. 26

Deflection instantaneous

and localized

Belt cushioned by

semi-pneumatic or

rubber disc type idlers –

preventing damage to belt

No opening at skirt upon

impact of material

Semi-pneumatic or rubber disc type idler arrangement,

placed as close together as possible

Fig. 28

V-Slot Chute

Powered by FlippingBook Publisher