Page 129 - publication

SEO Version

hdpe couplings

Introduction

Couplings

Outlets

Fittings

Val

ves &

Accesso

ries

High

Pressure

Advanced Copper

Method (IPS)

DI-LOK

®

Nipples

Plain-End

Fittings

HDPE

Couplings

Sock-It

®

Fittings

Stainless

Steel Method

Roll

Groovers

Installation

& Assembly

Special

Coatings

Design

Services

Technical

Data

Master Format

3 Part Specs.

Pictorial

Index

CTS Copper

System

www.anvilintl.com

129

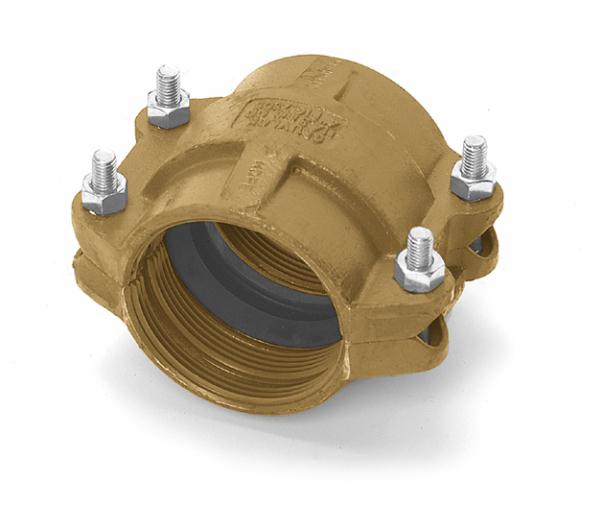

FIG. 7305

HDPE Coupling

The Gruvlok Figure 7305 couplings are designed for mechanically joining

HDPE (high density polyethylene) pipe and fttings. Each coupling uses

four bolts to drive the sharply machined housing teeth into the outside

of the pipe. The teeth are arranged in two banks, each bank consisting of

at least three rows of spiral teeth which effectively grip the pipe,

providing a secure mechanical joint with pressure capabilities exceeding

that of the HDPE pipe itself. The banks of teeth are positioned away

from the gasket enhancing the sealing ability of the gasket throughout

its operating temperature range.

The Figure 7305 features a low profle contoured housing with a ramp

along the outside diameter allowing the coupling to glide over most

obstacles, while long lengths of the pipeline are being relocated. This

cost effective easy to assemble mechanical joint is used to join SDR 32.5

to 7.3 wall thickness HDPE pipe conforming to ASTM D 2447, D 3000, D

3035, or F 714 and eliminates the need for costly fusion equipment.

material specifications

HOUSING:

Ductile Iron conforming to ASTM A 536, Grade 65-45-12

COATING:

Rust inhibiting paint – color: orange

Other Colors Available (IE: RAL3000 and RAL9000)

For other Coating requirements contact a Gruvlok Representative.

ANSI BOLTS & HEAVY HEX NUTS:

Heat treated, zinc electroplated, carbon steel oval-neck track bolts

conforming to ASTM A 183. Zinc electroplated carbon steel heavy hex

nuts conforming to ASTM A 563 Grade A or Grade B, or J995 Grade 2.

GASKETS:

Properties in accordance with ASTM D 2000

Grade E EPDM

(Green color code)

Service Temperature Range: -30°F to 230°F (-34°C to 110°C).

Recommended for water service, dilute acids, alkaline solutions,

oil free air and many chemical services.

NOT FOR USE IN PETROLEUM APPLICATIONS.

Grade T Nitrile

(Orange color code)

Service Temperature Range: -20°F to 180°F (-29°C to 82°C).

Recommended for petroleum applications, air with oil vapor,

vegetable and mineral oils.

NOT FOR USE WITH HOT WATER OR HOT AIR.

For specifc chemical applications, reference the Gruvlok Gasket

Recommendations section of the Gruvlok catalog.

WARNING:

1. Gruvlok products for HDPE pipe must be installed using Gruvlok Xtreme

TM

Temperature Lubricant.

2. The gasket temperature rating may exceed the manufacturer temperature

rating for the HDPE pipe. Consult the HDPE pipe manufacturer for the

temperature and pressure ratings.

GL-2.10

Powered by FlippingBook Publisher