Page 14 - publication

SEO Version

Introduction

www.anvilintl.com

14

GRUVLOK

®

– THE ENGINEERED COUPLING

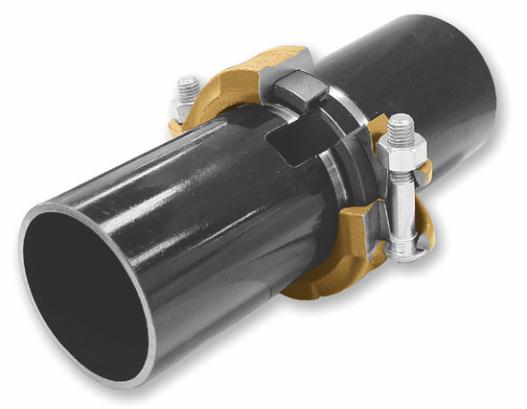

HOUSING (A) FLEXIBLE OR RIGID

The Gruvlok Coupling housing is designed to self-center

around the pipe. The housing encircles and retains the gasket

against the application of internal system pressure or vacuum.

The housing key sections ft into and engage the pipe-end

grooves around the entire pipe circumference, thus restraining

the pipe ends from separation due to the application of

internal pressure.

Flexible Couplings provide designed-in clearances between the

housing key sections and the pipe grooves to permit both

angular and longitudinal movement of the pipe. Rigid

couplings grip the pipe and lock the joint into position.

All housings are coated with paint for general service

applications. The paint serves to provide protection against

normal atmospheric corrosion. However, for couplings used in

corrosive environments, hot-dip galvanizing, and stainless steel

are available.

GASKET (B)

The unique single piece “C” style design of the gasket has been

engineered to provide a pressure responsive, leak-tight seal in

both pressure and vacuum applications without the aid of

external forces. The “lips” of the gasket are molded so that

upon installation onto the pipe ends they provide compression

against the pipe surface to establish the leak-tight seal.

The gasket cavity functions as a “pressure reservoir”. Pressure

within the pipe system is applied to the internal surfaces of the

gasket which increases the sealing force and enhances the

leak-tight seal. In vacuum systems, non-pressure-responsive

seals tend to “lift off” the pipe, producing leak paths. However,

the Gruvlok gasket reacts to the negative pressure (higher

outside atmospheric pressure) as to improve the sealing

capability of the gasket.

Gasket

Reaction

to Pressure

Gasket

Reaction

to Vacuum

BOLTS AND NUTS (C)

Heat treated oval neck track head bolts serve to connect and

secure the housing segments together. The oval neck design

prevents turning of the bolt while tightening the hex nut with

a single wrench. The bolt size and corresponding wrench (or

socket) size for the hex nuts are shown in the chart below.

A

B

D

C

GROOVED PIPE ENDS (D)

The ends of the pipe must

have a groove in them which

may be either cut grooved

or roll grooved. The grooved

pipe ends engage the

coupling keys, thus, providing

a self-restraining, mechanical

joint capable of resisting

the separation of the pipe

ends due to the application

of system pressure. The

groove diameters must be

dimensionally accurate to

obtain the maximum beneft

of the Gruvlok Coupling.

GL-2.10

Powered by FlippingBook Publisher