Page 26 - publication

SEO Version

couplings for grooved-end pipe

www.anvilintl.com

26

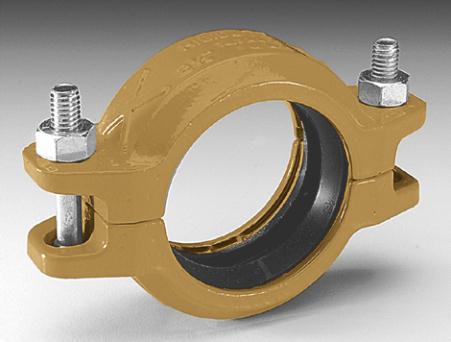

Fig. 7400

Rigidlite

®

Coupling

The Fig. 7400 Rigidlite Coupling from Gruvlok is specially

designed to provide a rigid, locked-in pipe connection to meet

the specifc demands of rigid design steel pipe and copper

tube systems. Fast and easy swing-over installation of the

rugged lightweight housing produces a secure, rigid pipe joint.

The Fig. 7400 Rigidlite Coupling is UL/ULC Listed and FM

Approved for 300 psi (20.7 bar) with roll grooved or cut

grooved steel pipe prepared in accordance with Gruvlok

grooving specifcations. Figure 7400 Rigidlite Coupling is

available with the Grade “E” EPDM, “C” Style Gasket intended

for use with the Gruvlok Advanced Copper Method.

MATERIAL SPECIFICATIONS

ANSI BOLTS & HEAVY HEX NUTS:

Heat treated, oval neck track head bolts conforming to ASTM A 183

Grade 2 with a minimum tensile strength of 110,000 psi and heavy hex

nuts of carbon steel conforming to ASTM A 563 Grade A or Grade B, or

J995 Grade 2. Bolts and nuts are provided zinc electroplated as standard.

METRIC BOLTS & HEAVY HEX NUTS:

Heat treated, zinc electroplated oval-neck track head bolts made of

carbon steel with mechanical properties per ISO 898-1 Class 8.8. Hex

nuts and bolts are zinc electroplated followed by a yellow chromate dip.

STAINLESS STEEL BOLTS & NUTS:

Stainless steel bolts and nuts are also available. Contact a Gruvlok

Representative for more information.

HOUSING:

Ductile Iron conforming to ASTM A 536, Grade 65-45-12.

COATINGS:

Rust inhibiting paint Color: ORANGE (standard)

Hot Dipped Zinc Galvanized (optional)

Other Colors Available (IE: RAL3000 and RAL9000)

For other Coating requirements contact a Gruvlok Representative.

GASKETS: Materials

Properties as designated in accordance with ASTM D 2000

Grade “E” EPDM

(Green color code) NSF 61 Certifed

-40°F to 230°F (Service Temperature Range)(-40°C to 110°C)

Recommended for water service, diluted acids, alkalies solutions, oil-

free air and many chemical services.

NOT FOR USE IN PETROLEUM APPLICATIONS.

Grade “T” Nitrile

(Orange color code)

-20°F to 180°F (Service Temperature Range)(-29°C to 82°C)

Recommended for petroleum applications. air with oil vapors and

vegetable and mineral oils.

NOT FOR USE IN HOT WATER OR HOT AIR

Grade “O” Fluoro-Elastomer

(Blue color code)

-20°F to 300°F (Service Temperature Range)(-29°C to 149°C)

Recommended for high temperature resistance to oxidizing acids,

petroleum oils, hydraulic fuids, halogenated hydrocarbons and

lubricants.

Grade “L” Silicone

(Red color code)

-40°F to 350°F (Service Temperature Range)(-40°C to 177°C)

Recommended for dry, hot air and some high temperature chemical

services.

GASKET TYPE:

Standard C Style

Flush Gap (1" - 8")

LUBRICATION:

Standard Gruvlok

Gruvlok Xtreme

TM

(Do Not use with Grade “L”)

DN 50 and DN 200

sizes are VdS approved.

GL-2.10

Powered by FlippingBook Publisher