SEO Version

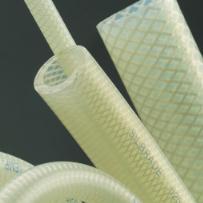

Silbrade

®

B r a i d R e i n f o r c e d S i l i c o n e H o s e

www.newageindustries.com

■

Open mesh polyester braiding incorporated within the walls of

silicone tubing

■

Made from FDA-sanctioned ingredients

■

Translucent natural color for visual contact with the flow

■

Able to resist extreme temperature variation: -80°F to 350°F

■

Odorless, tasteless, and inert

■

Excellent weatherability properties — resists U.V., ozone, gases,

moisture, and extreme temperatures

■

Offers far higher pressure capabilities than similarly-sized

unreinforced silicone tubing

■

Listed by the National Sanitation Foundation (NSF 51)

Notes

The construction of SILBRADE enables silicone

tubing to handle increased pressure applications.

SILBRADE offers outstanding resistance to

temperature extremes and is made from FDA-

sanctioned ingredients.

The flexible design and construction of

SILBRADE also allows excellent bend radii and

permits installation in restricted spaces without

impeding flow.

SILBRADE, a peroxide-cured product, contains

no sulphur or other acid-producing chemicals

thereby eliminating the possibility of staining,

corroding, or deteriorating other materials it

contacts. It is also resistant to ozone and U.V. over

long time periods.

Care is recommended in the selection of

fittings and clamps, as sharp barbed fittings or

unlined metal clamps could tear into the hose

wall and possibly cause a failure, especially at

elevated pressures.

SILBRADE is not recommended for

implantable or in-body uses or for continuous

steam applications.

SILBRADE may be low pressure steam

sterilized in-line or autoclaved at up to 250°F in a

normal autoclaving cycle. However, if exposed to

repeated steam sterilization or long-term high

temperature or pressure, silicone will eventually

relax and become gummy. It should then be

replaced.

Physical Properties**

Hardness, Shore A ±5 – Core

70

Hardness, Shore A ±5 – Cover

60

Tensile Strength, psi

1000

Elongation at Break, %

350

Brittle Temperature, °F

-80

Maximum Operating Temperature, °F

350

**Values listed are typical for the material used in

manufacture, except where noted, and are meant only as

a guide to aid in design. Field testing should be

performed to find the actual values for your application.

✪

Additional Services

LBS.

PER

100 FT.

5

7

9

11

13

17

23

28

36

WORKING

PSI AT 70°F

233

216

208

183

166

141

116

91

75

ID

(IN.)

1/8

3/16

1/4

5/16

3/8

1/2

5/8

3/4

1

OD

(IN.)

.365

.447

.520

.592

.655

.800

.965

1.100

1.380

STANDARD

LENGTH

(FT.)

100

100

100

100

100

100

50

50

50

PART NO.

290 0072

290 0149

290 0226

290 0303

290 0380

290 0457

290 0534

290 0611

290 0765

BURST PSI

AT 70°F*

699

648

624

549

498

423

348

273

225

Recommended Fittings & Clamps

■

Thermobarb® barbed fittings

■

Oetiker® ear type clamps

■

Kwik Clamp™ nylon double bond hose clamps

■

Worm gear clamps

WALL

(IN.)

.120

.130

.135

.140

.140

.150

.170

.175

.190

Cut coils are available; charges apply — call for details.

Add length suffix to part number when ordering. Example: 100 ft. of 1/8” I.D. x .365” O.D.

hose is part number 290 0072-100.

*The burst pressure can be expected to decrease by at least 20% for each 200°F increase

up to 350°F.

BOLD

indicates the critical dimension for fittings application.

Powered by FlippingBook Publisher