SEO Version

200

Parker Industrial Hose Customer Service

866 810 HOSE (4673) 800 242 HOSE (4673)

Strongsville, OH

South Gate, CA

Eastern USA

Western USA

www.safehose.com

e-mail: indhose@parker.com

Petroleum – LPG

(Continued on the following page)

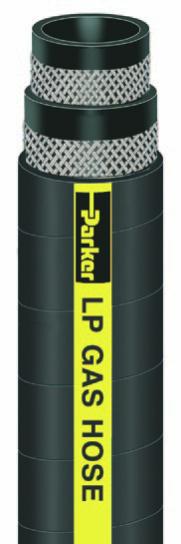

LP Gas Hose

UL21, CGA Type I

Series 7232

Series 7232 is a large diameter, fexible liquefed petroleum gas (LPG)/propane transfer hose

for large volume bulk loading/unloading and vibration-resistant onboard vehicle connections.

Te hose meets all Underwriters Laboratories (UL21) and Canadian Gas Association (CGA

Type I) requirements. Te construction incorporates multiple braids of textile reinforcement

for kink resistance and superior coupling retention. Te perforated cover is resistant to mild

chemicals, oil and ozone. Series 7232 is available in long lengths and factory-tested assemblies

in popular confgurations.

NOTE:

Refer to the Safety and Technical section of this catalog for safety, handling and use

information.

Series 7232 and DOT:

LPG hose assemblies installed on on-road vehicles must meet

Department of Transportation (DOT) requirements. Factory assemblies (all sizes) are pressure

tested, one of the fttings is etched with a unique DOT certifcation number, and a document

incorporating the identical certifcation number accompanies each assembly. Metal DOT

identifcation bands are also available/attached for an additional charge at customer request.

Contact Parker.

Series 7232 and Natural Gas:

Te molecules of natural gas are small, enhancing their ability to

permeate through standard rubber hose constructions. Te permeation process is more rapid

as the working pressure increases, and natural gas accumulates with potentially dangerous

consequences. Series 7232 may be used for natural gas service, but ONLY under ALL of the

following conditions:

• Te application must be in a well-ventilated environment: Outdoors, or indoors with

signifcant continuous air movement.

• Series 7232 is not to replace fxed/rigid pipe where that material is more appropriate due

to reduced permeation and overall strength and durability. Use rigid pipe, non-permeable

tubing or hose with barrier constructions to convey natural gas whenever possible.

Series 7232 and Compressed Natural Gas (CNG):

Series 7232 is not to be used for any CNG

application, including fuel dispensing, on-board vehicle fuel lines, or fuel transfer.

Series 7232 and Anhydrous Ammonia (NH

3

):

Series 7232 is not for use with anhydrous ammonia.

Tube:

Black nitrile

Reinforcement:

Multiple textile braids

Cover:

Black chloroprene; perforated wrapped fnish

Temp. Range:

-40°F to +180°F (-40°C to +82°C) (The hose construction is capable of this

rating, but LP Gas should NEVER be conveyed over 140°F/60°C)

Brand Method:

Side one:

Embossed

Side two:

Black text on yellow stripe

Brand Example:

Side one (Embossed):

PARKER SERIES 7232 CGA TYPE I CAUTION - LP

GAS HOSE MH6737 C U

R

®

US ISSUE NO. XXXX 350 PSI MAX WP MADE IN

USA (DATE CODE)

Side two (Stripe):

PARKER LP GAS HOSE

Design Factor:

5:1

Industry Standards:

UL21; CAN/CGA-8.1-M86 Type I; optional DOT factory hose assembly

testing and marking available. Contact Parker.

Applications:

• LP gas/propane

• Bulk loading/unloading, in-plant tank transfer, transport

• Agriculture, commercial and residential heating, construction, general industrial

Vacuum:

Not recommended

Compare to:

Boston Blackline (LPG); Gates LP350; Thermoid Type 65

Packaging:

Cartons, reels

R

Powered by FlippingBook Publisher