Page 381 - Cat4800-Oct2011

SEO Version

367

Parker Industrial Hose Customer Service

866 810 HOSE (4673) 800 242 HOSE (4673)

Strongsville, OH

South Gate, CA

Eastern USA

Western USA

www.safehose.com

e-mail: indhose@parker.com

Welding

SIAMEEZ

®

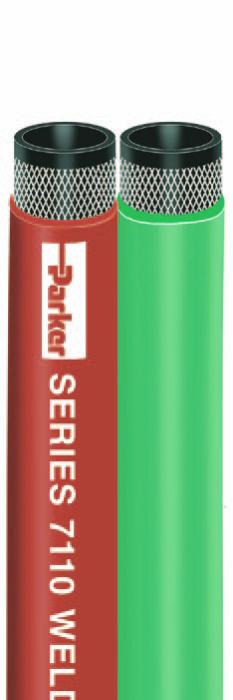

Grade RM Twin Line Welding Hose

Red – Acetylene Only; Green – Oxygen Line

ARPM IP-7

Series 7110

Series 7110 is a twin line welding hose featuring a fame resistant and oil resistant cover.

Te red line is compatible ONLY with acetylene fuel gas, and the green line is compatible

with oxygen. Te non-blooming tube minimizes the migration of combustible waxes or

plasticizers to the surface of the rubber, and the multiple plies of textile reinforcement

provide fexibility. Series 7110 is also available in factory-fabricated and tested hose

assemblies in popular confgurations.

Tube:

Black synthetic rubber

Reinforcement:

Multiple textile plies

Cover:

Red (acetylene) or green (oxygen) synthetic rubber; smooth fnish

Temp. Range:

-40°F to +200°F (-40°C to +93°C)

Brand Method:

White ink on red hose

Brand Example:

PARKER 7110 WELDING

!

WARNING ACETYLENE ONLY (ID) MAX

WP 200 PSI ARPM IP-7-(YEAR) STD DUTY GRADE RM COUPLE

WITH ONE INCH FERRULES MADE IN USA (DATE CODE)

Design Factor:

4:1

Industry Standards:

ARPM IP-7

Applications:

•

Red:

Acetylene ONLY;

Green:

Oxygen

• Bending, brazing, cutting, fabricating, gouging, joining, piercing, pre-

heating, post-heating, severing, soldering, straightening, surfacing,

trimming

• Assembly and fabrication shops, construction, factories, foundries,

mines, oil rigs, plumbing, rail yards, salvage, scrapyards, shipyards,

steel mills

Vacuum:

Not recommended

Compare to:

Thermoid Tuline Grade RM; Veyance Gemini Twinline Grade RM

Packaging:

Reels; ftted hose assemblies shrink-wrapped and labeled in master

cartons

Part

Number

ID

(in)

ID

(mm)

Reinf

Plies

OD

(in)

OD

(mm)

Approx

Wt

(lbs/ft)

Approx

Wt

(kg/ft)

Min

Bend

Rad

(in)

Min

Bend

Rad

(mm)

Max

Rec

WP

(psi)

Max

Rec

WP

(bar)

Std Pack

Qty

(ft)

Stock

Status

**

7110-191

3/16 4.8 2 0.438 11.1 0.16 0.07 2.0 50.8 200 13.8 800

N

7110-251

1/4 6.4 2 0.531 13.5 0.21 0.10 2.5 63.5 200 13.8 800

Y

7110-311

5/16 7.9 2 0.594 15.1 0.28 0.13 3.0 76.2 200 13.8 750

N

7110-381

3/8 9.5 2 0.656 16.7 0.32 0.15 4.0 101.6 200 13.8 700

N

Factory Assemblies:

Available from stock in popular confgurations. See the following page.

* Couplings:

As specifed in CGA publication E-1. Bulk welding hose couplings are not sold separately by Parker.

**

Stock:

“Y” indicates stocked item; “N” indicates non-stocked item. Stock status subject to change. Contact Parker Customer Service.

WARNING!

Do not attempt to re-couple, repair or splice hose assemblies; replace all assemblies that show signs of abrading, abuse,

age, damage or fatigue. Refer to ARPM IP-7, Specifcations for Rubber Welding Hose and Hose Technical Bulletin 11-5, Guide for Use,

Maintenance and Inspection of Welding Hose. Refer to CGA Safety Bulletin SB-11,

Use of Rubber Welding Hose

. Refer to the Safety &

Technical Information section of this catalog for further information.

!

Powered by FlippingBook Publisher