Page 194 - Cat4800-Oct2011

SEO Version

Page 99 - Cat4800-Oct2011

SEO Version

85

Parker Industrial Hose Customer Service

866 810 HOSE (4673) 800 242 HOSE (4673)

Strongsville, OH

South Gate, CA

Eastern USA

Western USA

www.safehose.com

e-mail: indhose@parker.com

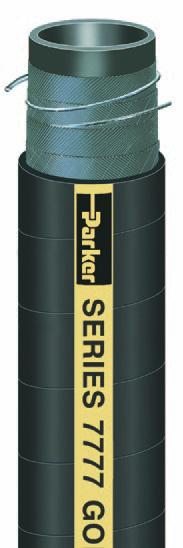

Composite

Bottom Loading Hose

Series 4500

Inner Wire:

Galvanized steel (G)

Inner Liner:

Polypropylene fabric

Hose Wall:

Multiple layers of fabric/flm/tubes

Cover:

Blue PVC coated polyester

Outer Wire:

Galvanized steel (G)

Temp Range:

-40°F to +212°F (-40°C to +100°C)

Brand Method:

Black text on gold stripe

Brand Example:

PARKER SERIES 4500 BOTTOM LOADING HOSE 200 PSI MAX WP

MADE IN USA

Design Factor:

4:1

Industry Standards:

None applicable

Applications:

Hose loading arms in bottom loading applications at bulk distributing and

refning facilities

NOTE:

Not for dry material service.

Vacuum:

Full

Compare To:

Perafex BL-GGP Bottom Loading; Tift 901/401 Bottom Loading;

Uni-Chem Uni-BL; Wilcox 4124SS/4121SG

Standard Wire:

G (Galvanized) inner and outer

Available Wire Options:

See table below

Coupling Rec:

Permanently attached one-piece TTMA (Truck Trailer Manufacturers

Association) fanges. Refer to page 387 for standard factory coupling

options.

Assemblies:

Per customer requirement; hydrostatically tested to 150% of the rated

working pressure. Contact Parker.

Part

Number

ID

(in)

ID

(mm)

Approx

Wt

(lbs/ft)

Min Bend

Rad

(in)

Max

Rec WP

(psi)

Max Lg

(ft)

4500GG-3000

3

76.2

2.0

9.5

200

70

4500GG-4000

4

101.6 4.4

16.0 200

70

Available Component Materials

Component

Description

Alpha Designation

in Hose Part Number

Inner Wire Galvanized Steel

G

Outer Wire Galvanized Steel

G

Inner Liner Polypropylene

n/a (Standard)

Couplings Carbon Steel

–

Stainless Steel

–

See page 387 for additional coupling materials data.

WARNING!

It is the responsibility of the user to determine if the hose

is suitable for the application. Elevated temperatures can change the

chemical resistance ratings. Many chemicals will become more aggressive

as temperatures increase, reducing the ability of hose materials to

withstand them. Contact Parker for chemical compatibility data at elevated

temperatures. Refer to the Safety and Technical section of this catalog for

safety, handling and use information. Refer to the Composite Hose table in

the Chemical Guide section of this catalog to determine compatibility with

specifc chemicals. Contact Parker for additional chemical compatibility

information. If no data exists, users are required to perform compatibility

testing at the desired temperature.

!

Powered by FlippingBook Publisher