Page 14 - ThermoidPowerTransnmissionBeltsBrochure(HBDTHE-18770)

SEO Version

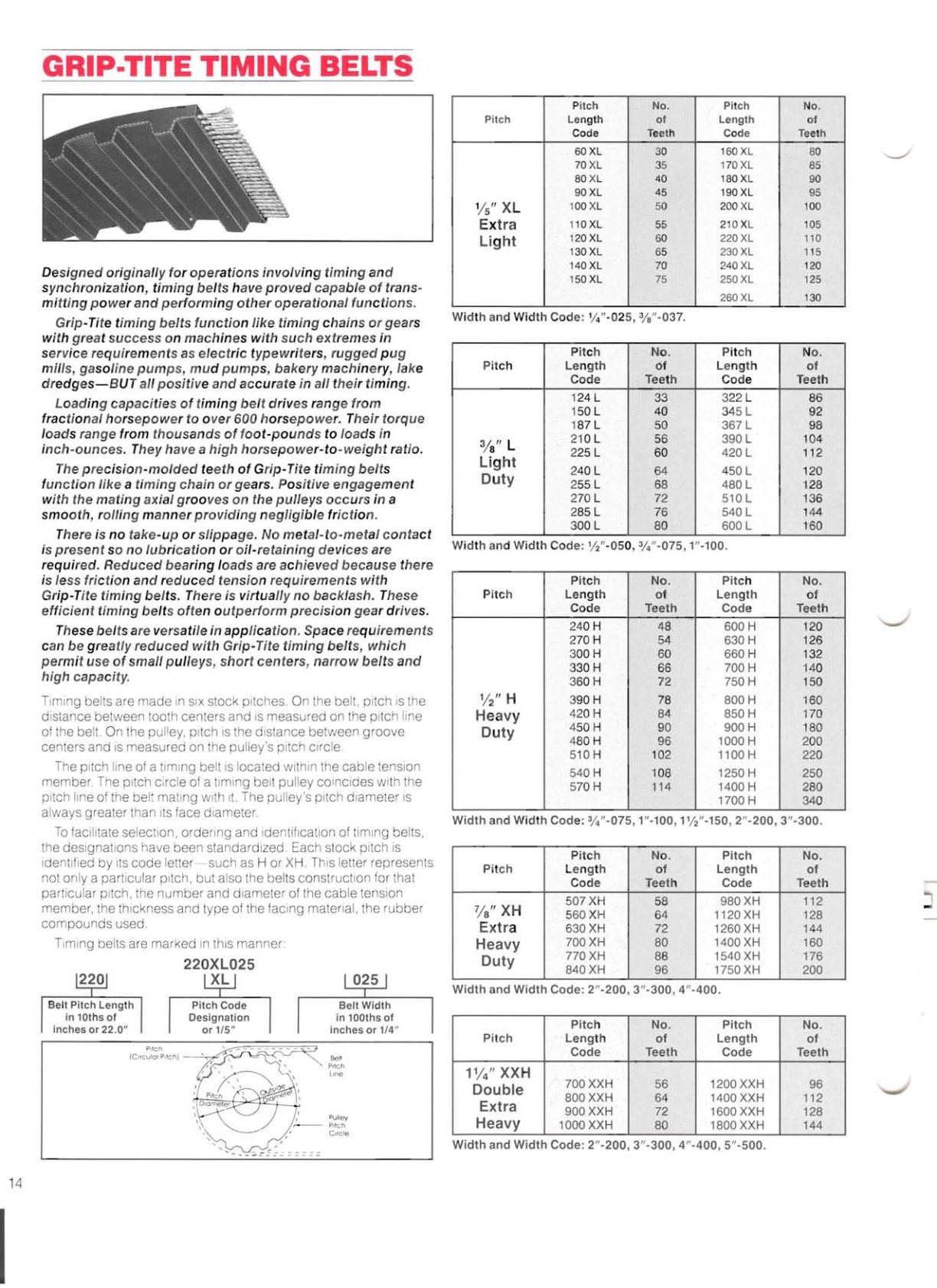

GRIP-TITE TIMING BELTS

Pitch

Pitch

Length

Code

No.

of

Teeth

Pitch

Length

Code

No.

of

Teeth

60XL

30

160XL

80

70XL

35

170XL

85

80XL

40

180 XL

90

90XL

45

190XL

95

Vs"

XL

100XL

50

200 XL

100

Extra

110XL

55

210XL

105

Light

120XL

60

220 XL

110

130XL

65

230 XL

115

140XL

70

240 XL

120

150XL

75

250 XL

125

260 XL

130

Designed originally for operations involving timing and

synchronization, timing belts have proved capable of trans

mitting power and performing other operational functions.

Grip-Tite timing belts function like timing chains or gears

with great success

on

machines with such extremes in

service requirements

as

electric typewriters, rugged pug

mills, gasoline pumps, mud pumps, bakery machinery, lake

dredges-BUT all positive and accurate in all their timing.

Loading capacities of timing belt drives range from

fractional horsepower

to

over 600 horsepower. Their torque

loads range from thousands of foot-pounds

to

loads in

inch-ounces. They have

a

high horsepower-to-weight ratio.

The precision-molded teeth of Grip-Tite timing belts

function like

a

timing chain or gears. Positive engagement

with the mating axial grooves

on

the pulleys occurs in

a

smooth, rolling manner providing negligible friction.

There is

no

take-up or slippage. No metal-to-metal

contact

is present

so no

lubrication or oil-retaining devices are

required. Reduced bearing loads are achieved because there

is less friction and reduced tension requirements with

Grip-Tite timing belts. There is Virtually

no

backlash. These

efficient timing belts often outperform precision gear drives.

These belts are versatile in application.

Space

requirements

can

be greatly reduced with Grip-Tite timing belts, which

permit use of small pulleys, short centers, narrow belts and

high capacity.

Timing belts are made in six stock pitches. On the belt, pitch is the

distance between tooth centers and is measured on the pitch line

of the belt On the pulley, pitch is the distance between groove

centers and is measured on the pulley's pitch Circle

The pitch line of a timing belt is located Within the cable tension

member. The pitch circle of a timing belt pulley coincides with the

pitch line of the belt mating with it. The pulley's pitch diameter is

always greater than its face diameter.

To facilitate selection, ordering and Identification of timing belts,

the designations have been standardized Each stock pitch is

Identified by Its code letter-such as H or XH. This letter represents

not only a particular pitch, but also the belts construction for that

particular pitch, the number and diameter of the cable tension

member, the thickness and type of the facing material, the rubber

compounds used.

Timing belts are marked In this manner

220XL025

Width and Width Code: 1J4'-025, %"-037.

Pitch

Pitch

Length

Code

No.

of

Teeth

Pitch

Length

Code

No.

of

Teeth

3/8 "

L

Light

Duty

124 L

150 L

187 L

210 L

225 L

240 L

255 L

270 L

285 L

300 L

33

40

50

56

60

64

68

72

76

80

322 L

345 L

367 L

390 L

420 L

450 L

480 L

510 L

540 L

600 L

86

92

98

104

112

120

128

136

144

160

Width and Width Code: '/2"-050, %"-075, 1"-100.

Pitch

Pitch

Length

Code

No.

of

Teeth

Pitch

Length

Code

No.

of

Teeth

240H

48

600 H

120

270H

54

630 H

126

300 H

60

660 H

132

330 H

66

700 H

140

360 H

72

750 H

150

1,12"

H

390 H

78

800 H

160

Heavy

420 H

84

850 H

170

Duty

450 H

480 H

90

96

900 H

1000 H

180

200

510 H

102

1100 H

220

540 H

101;!

1250 H

250

570 H

114

1400 H

280

1700 H

340

Width and Width Code: %"-075, 1"-100,

1'12"-150,

2"-200, 3"-300.

Pitch

Pitch

Length

Code

No.

of

Teeth

Pitch

Length

Code

No.

of

Teeth

%"XH

Extra

Heavy

Duty

507 XH

560XH

630XH

700XH

770XH

840XH

58

64

72

80

88

96

980XH

1120 XH

1260 XH

1400XH

1540 XH

1750XH

112

128

144

160

176

200

Width and Width Code: 2"-200, 3"-300, 4"-400.

XL

Pitch

Pitch

Length

Code

No.

of

Teeth

Pitch

Length

Code

No.

of

Teeth

1%"

XXH

Double

Extra

Heavy

700XXH

800XXH

900XXH

1000 XXH

56

64

72

80

1200XXH

1400XXH

1600XXH

1800XXH

96

112

128

144

Width and Width Code: 2"-200, 3"-300, 4"-400, 5"-500.

14

Powered by FlippingBook Publisher