Page 95 - DPL413 Complete Catalog for web_wm

Basic HTML Version

Boss Fittings

93

DPL413

877.963.4966 • dixonvalve.com

D

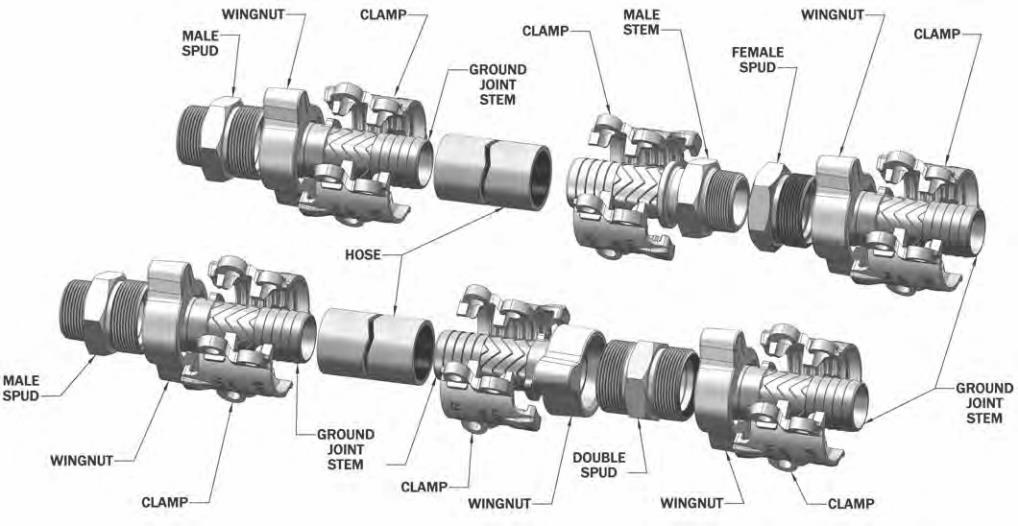

Boss Coupling System

Features:

The spud part of the coupling serves as one half

of the connection and is usually fixed to the equipment. The

stem part that is clamped to the hose is the other half. The two

halves are connected or disconnected by rotating the wing nut

onto the spud. When connected they achieve a mechanical,

as well as, a pressure seal.

Services:

Boss couplings are all-purpose hose couplings,

universally recommended for steam hose connections. They

are also widely used for air, water, fluid petroleum, chemicals

and liquid petroleum gas up to 1" ID. Boss couplings can be

applied to many types of rubber, synthetic, plastic, metallic

or semi-metallic hose. Consult the factory for specific media

capabilities.

Purpose:

Boss couplings supply a convenient threaded fitting

to connect two lengths of hose, or a single length to a male or

female threaded (NPT) outlet.

Material:

•

stem: ¼" - 1" plated steel, 1¼" - 4" plated iron, 6" tubular

steel

•

spud: ¼" - 1" plated steel, 1¼" - 6" plated iron

•

wing nut: ¼" plated steel, 3/8" - 6" plated iron

Seal Types:

•

ground joint: copper or polymer seats

•

washer: Klingersil

®

C-4401

Worn-out hose couplings can be dangerous. They should

be checked regularly and replaced when necessary. Each

coupling user should review applications and add safety

devices where indicated.