Page 25 - GarlockFluidSealing2010

SEO Version

A-23

Installation Instructions

1. Remove all of the old packing from the stuffng box.

Clean box and stem thoroughly and examine stem

for wear and scoring. Replace stem if wear is exces-

sive. Recommended surface fnishes are 32 (micro

inches) AARH on the stem, and 125 (micro inches)

AARH maximum on the box bore.

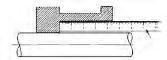

2. Measure and record stem diameter, stuffng box

bore and box depth. To determine the correct pack-

ing size, measure the diameter of the stem (inside

the stuffng box area if possible), and the diameter of

the stuffng box bore. Subtract the I.D. measurement

from the O.D. measurement, and divide the differ-

ence by two. This is the required cross-sectional

size.

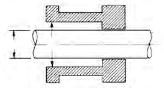

3. Always cut the packing into individual rings. Never

wind the packing into a coil in the stuffng box. Rings

should be cut with a butt joint. Cut rings by using a

spare stem, a mandrel with the same diameter as

the stem or a packing cutter. The illustration shows

how to use a mandrel to cut packing.

Hold the packing tightly on the mandrel, but do not

stretch excessively. Cut the ring and insert it into the

stuffng box, making certain that it fts the packing

space properly. Each additional ring can be cut in

the same manner.

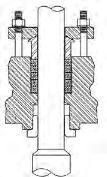

4. Install one ring at a time. Make sure it is clean, and

has not picked up any dirt in handling. Seat each

ring frmly, making sure it is fully seated before the

next ring is installed. Joints of successive rings

should be staggered and kept at least 90° apart.

When enough rings have been individually seated

so that the nose of the gland follower will reach

them, individual tamping of the rings should be

supplemented by the gland follower. Bring down the

gland follower and apply load with the gland bolts.

5. After the last ring is installed, bring down the gland

follower and apply 25% to 35% compression to the

entire packing set. If possible, record the gland nut

torque values and actuate the valve through fve (5)

complete cycles (ending with the stem in the down

position). Retighten the gland bolt nuts to the pre-vi-

ously recorded torque value after each full actuation.

Step 1

Step 2

Ruler

I.D.

O.D.

Do Not

Stretch

Packing

Mandrel

Step 3

Steps 4 and 5

Butt Cut

Joints

Valve Stem Packing

Powered by FlippingBook Publisher