Page 26 - GarlockFluidSealing2010

SEO Version

A-24

Pump Packing

1. Remove all the old packing with packing hooks, be-

ing careful not to damage the shaft or sleeve. This

means all rings, even the lantern ring and the rings

below the lantern. Clean the stuffng box and exam-

ine the shaft and sleeve. Replace any worn parts

that are scored or deeply grooved.

2. Measure and record shaft diameter, stuffng box

bore and box depth. To determine the correct pack-

ing size, measure the diameter of the shaft and the

stuffng box bore. Subtract the shaft diameter from

the bore diameter and divide the difference by two.

This is the required cross-sectional size.

3. Always cut the packing into individual rings. Never

wind the packing into a coil in the stuffng box. Rings

should be cut with a butt joint. Cut rings by using a

mandrel with the same diameter as the shaft in the

stuffng box area. If there is no wear, rings can be

cut on the shaft outside the stuffng box.

Hold the packing tightly on the mandrel, but do not

stretch excessively. Cut the ring and insert it into the

stuffng box, making certain that it fts the packing

space properly. Each additional ring can be cut in

the same manner.

4. Install one ring at a time. Make sure it is clean, and

has not picked up any dirt in handling. Lubricate the

I.D. of each ring lightly. Start one end and then the

other, butted closely. Work around circumference

from either or both directions. Joints of successive

rings should be staggered and kept at least 90°

apart. Each individual ring should be frmly seated

with a tamping tool. When enough rings have been

individually seated so that the nose of the gland fol-

lower will reach them, individual tamping should be

supplemented by the gland.

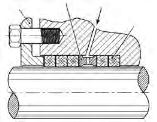

5. If a lantern ring is provided, make sure the lantern

ring is installed under the pipe tap hole.

6. After the last ring is installed, bring the follower

down on the packing and fnger-tighten the gland

nuts. Do not jam the packing by excessive gland

loading. Start pump, and tighten the bolts until leak-

age is decreased to a tolerable minimum. Make sure

gland bolts are tightened evenly. Stopping leakage

entirely at this point will cause the packing to burn

up.

7. Allow packing to leak freely upon startup after re-

pack. Gradually reducing leakage during the frst

hour of operation will result in a better seal over a

Step 1

Step 2

Ruler

Step 3

Steps 5 and 6

I.D.

O.D.

Butt Cut

Joints

Do Not

Stretch

Packing

Mandrel

Gland

Follower

Lantern

Ring

Flush

Port

Braided

Packing

longer period of time. Tighten the gland nuts one fat

at a time until the desired leakage is obtained, and

the pump is running cool.

Powered by FlippingBook Publisher