SEO Version

A-26

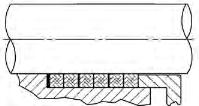

Gasket Spacers

Gasket spacers are used in conjunction with braided

packing rings to:

■

Close up the clearances around the inside diameter

of the packing set, keeping solid particles from pro-

gressing through the packing set along with the liquid

leakage

■

Act as a throttle bushing and reduce the pressure on

the outboard side of the spacer, in applications where

the leakage rate is relatively high

■

Keep the packing from extruding beyond the stuffng

box bottom, where there are excessive clearances

between the I.D. of the stuffng box bottom and the

shaft O.D. (This problem may occur through wear,

corrosion, or simply the way a piece of equipment is

manufactured)

In applications involving high stuffng box pressures

(particularly reciprocating pumps) gasket spacers are

also used to:

■

Reduce the amount of leakage that occurs through

the body of the braid, by forcing leakage to the I.D. of

the packing set and eliminating O.D. leakage

■

Keep the packing square, restrict packing movement,

and prevent packing rollover and premature failure

caused by excessive frictional forces

Gland Load

Garlock recommends using one of these two

methods to determine the proper gland load on a valve

packing set.

Percent Compression Method

This method simply determines the distance the set

should be compressed in order to achieve a seal. The

recommended percent compression varies with pack-

ing style.

■

9000-EVSP Simplifed

30% compression

QUICKSET

®

9001

30% compression

■

70#

/

ft

3

density GRAPH-LOCK

®

25% compression

70#

/

ft

3

density #98 sets

25% compression

■

90#

/

ft

3

density GRAPH-LOCK

®

20% compression

90#

/

ft

3

density #98 sets

20% compression

■

Garlock braided packing only 25% compression

In cases where the system pressure is very high

(over 2,500 psi or 72 bar), higher compression may be

required to achieve a seal.

Predetermined gland bolt torque method

This method determines a more precise gland load.

The bolt torque depends upon packing size, gland bolt

size, packing style system pressure, and the number of

bolts. The gland studs and nuts must be in good condi-

tion, cleaned with a wire brush and well-lubricated with

a suitable grease.

Use the following equation to determine the appro-

priate bolt torque:

BoIt torque =

(Bore dia.

2

- Stem dia.

2

) x (Gland bolt dia.) x (Load factor)

76.39 x (No. of bolts)

Where: Bolt torque is in ft. lbs.

Bore, stem, and bolt diameters are in inches

Load factor is in psi

The load factor is determined by the following:

■

For a 9000-EVSP Simplifed set, a 9001 QUICK-

SET

®

or a Style #98 and GRAPH-LOCK

®

set:

LF = 1.5 system pressure or 3,800 psi (whichever is greater)

■

When using any other Garlock packing:

LF = 1.5 system pressure or 5,500 psi (whichever is greater)

* Patent pending

Stealth Packing Set* Option

■

Optimal dry running situation—eliminate fush and

lantern ring

■

Combines Garlock Style 3530 GYLON

®

spacers

with Style 1304 or 1333-G cut rings

■

Contact Applications Engineering for details

Stealth Packing Set Spacer and Ring Arrangement

Style 1304

or 1333-G

Packing

Style 3530

Black GYLON

®

Spacers

Powered by FlippingBook Publisher