Page 36 - ConveyorBeltMaintenanceManual2010

SEO Version

BEST PRACTICE NO. 2

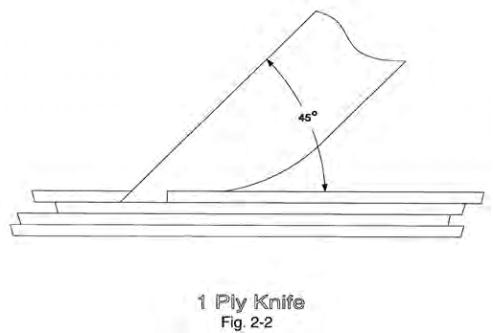

Use the proper ply knives and techniques to avoid nicking the adjacent fabric plies while

stripping down the belt.

Nicking the adjacent fabric ply effectively reduces the tension rating of the belt, because the tensionmembers (warp cords)

are disabled if they are cut or nicked. Top splicers use top quality tools such as the correct single-ply knives designed

specifically for this operation. Utility knives are not acceptable and must not be used for this precise operation.

BEST PRACTICE NO. 3

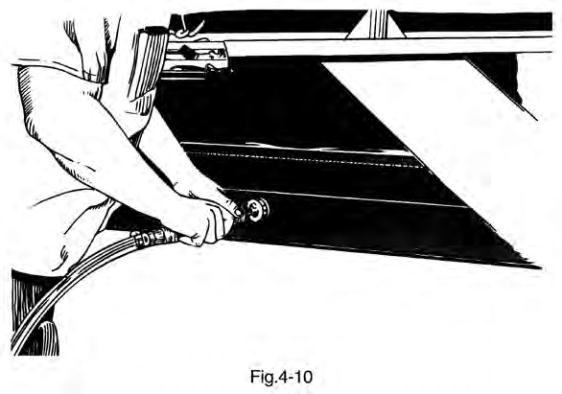

Buff the rubber surfaces only. Never directly buff the fabric.

The fabric plies of all Goodyear Engineered Products belts are coated with various “dip” coats that enhance the

adhesion of the rubber to the fabric. These dip coats should not be buffed off when preparing the belt splice. Reduced

ply and cover adhesion will result. If residual rubber must be buffed off after stripping down the step, it must be done

carefully so that the buffer wheel does not actually touch the fabric. Severe overbuffing will reduce belt strength and

integrity by damaging both warp and fill cords. The buffer wheel should not exceed 2000 RPM. A fabric cement known

as “kicker” should be used to replace the dip on exposed fabric.

Only one ply is

cut. The adjacent

ply is not harmed

in any way.

34

INSTALLATION, MAINTENANCE & TROUBLESHOOTING GUIDE

t e n b e s t p r a c t i c e s i n c o n v e y o r b e l t s p l i c i n g

Powered by FlippingBook Publisher