Page 37 - ConveyorBeltMaintenanceManual2010

SEO Version

BEST PRACTICE NO. 4

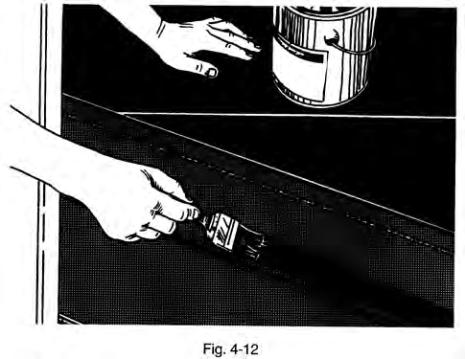

Allow cements and solvent to dry completely

before assembling the splice. When checking

the cement for wetness/dryness, never use the

palm of the hand or the palm side of the

fingers. Oils may be transferred to the surface,

which may reduce the adhesion value in this

area. It is recommended to use the back side

of the fingers.

When a belt splice is assembled and cured before the cement has had sufficient time to dry, the heat from the

vulcanizer will cause the solvents and carriers in the cement to vaporize and form bubbles / blisters. These bubbles /

blisters are called “ply and/or cover blows.” They will prevent adhesion between the plies and covers. If the surface

area of the ply or cover blow is large enough and/or numerous, the strength of the splice is severely limited.

Ply and cover blows can also occur when cements and solvents are not allowed to reach room temperature after

removal from cold storage because water condensation occurred on the cold surface.

Reliable splicers will allow sufficient time for cements to dry before assembly and for cold materials to warm up.

Additionally, conscientious splicers will not try to accelerate the drying process by using heat guns or hair dryers, since

they can cause a skin to form on the surface of still-wet cements. Space heaters may be used to accelerate cement-

drying time, as long as safety is not compromised in any way.

BEST PRACTICE NO. 5

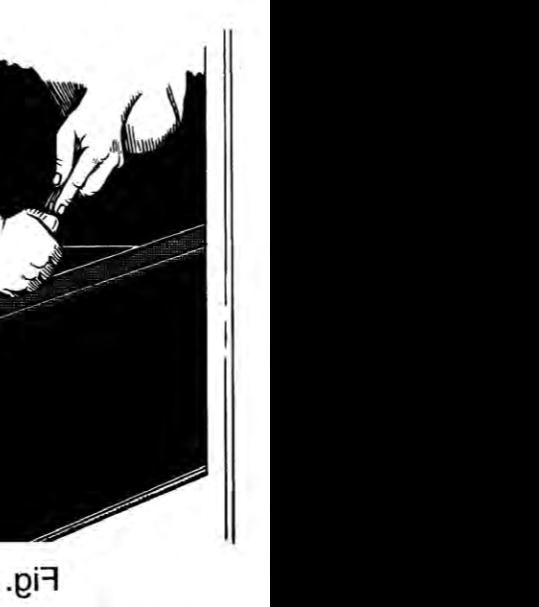

Avoid over-prodding the fabric

when lifting the plies.

The right tools and methods will ensure that the fabric

plies are not damaged when they are lifted. Prodding

tools must have smooth, rounded corners. Prodding

tools should be checked for possible burrs or nicks

before each use.

35

INSTALLATION, MAINTENANCE & TROUBLESHOOTING GUIDE

t e n b e s t p r a c t i c e s i n c o n v e y o r b e l t s p l i c i n g

Powered by FlippingBook Publisher