Page 40 - ConveyorBeltMaintenanceManual2010

SEO Version

38

INSTALLATION, MAINTENANCE & TROUBLESHOOTING GUIDE

t e n b e s t p r a c t i c e s i n c o n v e y o r b e l t s p l i c i n g

BEST PRACTICE NO. 10

Align the splice squarely and properly.

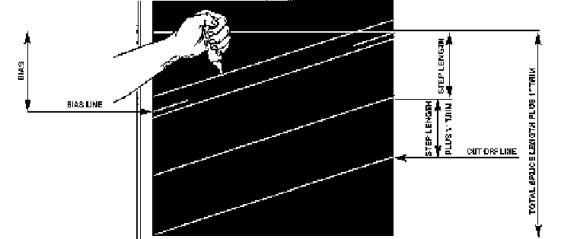

Splices that are not aligned cause many problems. Tracking and training problems can frequently be traced

back to splices that are not square. Additionally, splices that are out-of-square do not distribute the tension

load evenly across the splice, and thus can cause premature splice failure. Reputable splicers go to great

lengths to make certain that the belt is clamped securely and that all measurements, master lines and cuts are

precise and accurate.

Conclusion

When the “Ten best practices in conveyor belt splicing” discussed above are incorporated into your

standard operating procedures and specifications, and the conveyor system is properly engineered and well-

maintained in the first place, a dependable, long splice life can be obtained.

For further information regarding:

• Goodyear EP Total Belt Service

™

splice materials

• Goodyear EP Conveyor Belt Splicing Manual.

• Goodyear EP Splice Network members

• Any other technical or product question

Please consult your local Goodyear EP Technical Manager (GTM).

Powered by FlippingBook Publisher