Page 157 - publication

SEO Version

gruvlok installation and assembly

Introduction

Couplings

Outlets

Fittings

Val

ves &

Accesso

ries

High

Pressure

Advanced Copper

Method (IPS)

DI-LOK

®

Nipples

Plain-End

Fittings

HDPE

Couplings

Sock-It

®

Fittings

Stainless

Steel Method

Roll

Groovers

Installation

& Assembly

Special

Coatings

Design

Services

Technical

Data

Master Format

3 Part Specs.

Pictorial

Index

CTS Copper

System

www.anvilintl.com

157

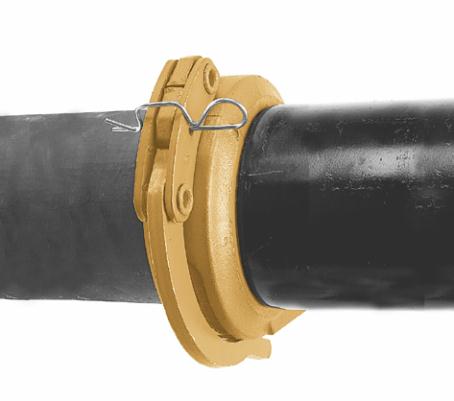

FIG. 7003

Hingelok™ Coupling

1

Check & lubricate gasket—

Check gasket to be sure it is compatible for

the intended service. Apply a thin coating of

Gruvlok lubricant to outside and sealing lips of

the gasket. Be careful that foreign particles do

not adhere to lubricated surfaces.

2

Gasket Installation—

Slip the

gasket over the pipe end making sure the

gasket lip does not overhang the pipe end.

3

Alignment—

After aligning the two

pipe ends, pull the gasket into position

centering it between the grooves on each pipe.

Gasket should not extend into the groove on

either pipe.

4

Housings—

Put one half of the open

coupling over the gasket as the coupling

keys ft frmly into the grooves on each pipe

end. Swing the other half of the coupling into

position around the gasket and into the grooves.

5

Lock coupling—

Fit the nose of the

locking handle in the notch of the opposite

housing. Press frmly down on the handle until it

makes contact with the coupling housing. Insert

locking pin into handle linkage to secure handle

in closed position. (See Caution.)

6

Assembly is complete—

Visually

inspect the pipe joint to assure the coupling

keys are fully engaged in the pipe grooves and

the bolt pads are in frm even metal-to-metal

contact on both sides of the coupling.

CAUTION:

1) Hammering or banging on the handle or coupling housing could cause serious damage

to the locking device and coupling assembly. The result may be an unsuitable pipe joint

and unusable coupling assembly.

2) Care needs to be taken so that fngers do not get caught or pinched when handle is

placed in locked position as a result of cam action of handle assembly.

3) When re-using coupling and gasket, always inspect gasket for damage and hinge/

handle assembly for loosenenss, distortion or any other damage.

NOTE:

Remove locking pin from handle before opening coupling.

GL-2.10

Powered by FlippingBook Publisher