Page 169 - publication

SEO Version

gruvlok installation and assembly

Introduction

Couplings

Outlets

Fittings

Val

ves &

Accesso

ries

High

Pressure

Advanced Copper

Method (IPS)

DI-LOK

®

Nipples

Plain-End

Fittings

HDPE

Couplings

Sock-It

®

Fittings

Stainless

Steel Method

Roll

Groovers

Installation

& Assembly

Special

Coatings

Design

Services

Technical

Data

Master Format

3 Part Specs.

Pictorial

Index

CTS Copper

System

www.anvilintl.com

169

FTV-S (Straight) & FTV-A (Angle Body)

Tri-Service Valve

INSTALLATION:

1

The valve should be mounted to a spool piece on the discharge

side of the pump. Spool piece required is based on a minimum

recommended space of 12" for pump sizes 2" x 2" to 6" x 6" and 24" for

pump sizes 8" x 8" to 12" x 12".

2

It is not recommended to mount a valve directly to the pump as

this could cause undesirable noise in the system.

3

Suffcient clearance around the valve should be left for valve

removal or repair.

4

Install valve in the direction of the fow arrows on the valve body.

5

The valve can be mounted to fanged equipment using Gruvlok

Flange Adapter or industry standard grooved coupling, suitable for

system pressure and temperatures encountered.

6

The Gruvlok Tri-Service valve bodies have anti-rotation lugs on the

inlet and outlet. These lugs, combined with the Flange Adapters,

provide a ridged rotation free installation.

7

The valve body has been designed to handle the weight of the

pump on vertical in-line installations. The body is not designed to

support the piping weight. It is recommended that the piping be

supported by hangers. Pipe supports should be provided under the

valve and strainer bodies.

TYPICAL INSTALLATIONS

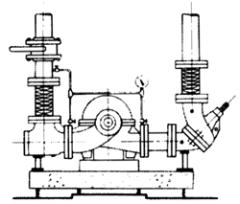

Base-Mounted Single Suction

Base-Mounted Double Suction

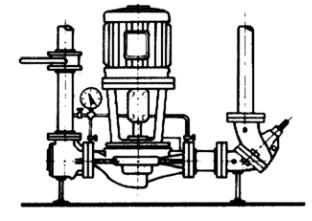

Vertical In-Line

LEGEND

Gruvlok ductile iron flange

adapters for ANSI 150# flanges

Gruvlok ductile iron flange

adapters for ANSI 300# flanges

Grooved end with 375 psi rated

pipe coupling

A

A

B

C

Temperature

°

C

Temperature

°

F

Note: for temperatures between 230

°

F and 300

°

F

(110

°

C and 149

°

C) specify Viton Elastomers.

Pressure (psi)

Pressure (kpa)

400

-46

°

-29

°

-18

°

10

°

38

°

66

°

93

°

110

°

-50

°

-20

°

-0

°

50

°

100

°

150

°

200

°

230

°

375

300

250

200

100

0

2,760

2,585

2,070

1,724

1,380

690

250

B & C

PRESSURE – TEMPERATURE LIMITS

FIELD CONVERSION

(Straight to Angle Pattern Valve)

1

Open valve at least one complete turn,

2

Remove the body bolts from valve body

using Allen Key.

3

Rotate one half of the valve body 180°

making sure the lower valve seat and “O”

Ring stay in position. Inspect the “O” Ring for

any cuts or nicks and replace if necessary.

4

Replace body bolts and torque evenly to

70 ft./lbs.

FLOW MEASUREMENT

Where approximate indication of fow is acceptable the Gruvlok Tri-Service valve can be used.

FLOW MEASUREMENT VALVE IN WIDE OPEN POSITION

Measure and record the differential pressure across the valve using a Flow Meter with high

pressure range transducer or pressure gauges with PMP adapters.

Refer to Tri-Service Performance Curves with valve in full open position (See Determining Flow

Rate with Valve in Throttled Position Section on page 165). Locate Pressure Differential on left

hand side of chart and extend line horizontally across to valve size being used. Drop line

vertically down and read fow rate from bottom of chart.

CAUTION

:

Safety glasses should be used and the probe should

not be left inserted into fttings for prolonged periods

of time (overnight, etc.), as leakage from the PMP may

occur when probe is removed.

GL-2.10

Powered by FlippingBook Publisher