Page 170 - publication

SEO Version

gruvlok installation and assembly

www.anvilintl.com

170

5

The correct positioning and

relationship of all components

comprising a Gruvlok Flange joint. The

Fig. 7012 Gruvlok Flange gasket must be

inserted so that the sealing lips face

toward the tube end and the mating

fange face and away from the Gruvlok

Flange itself.

NOTE: Design of the Gruvlok Flange

provides sealing only with the special

Gruvlok Flange gasket. Only Gruvlok

Flange gaskets may be used with Fig.

7012 Gruvlok Flanges.

Proper position

of gasket

sealing lips

Gasket

Flange,

pump,

tank,

valve,

etc.

Gruvlok

Flange

Grooved

Pipe

FLANGE ADAPTER INSTALLATION:

1

The Fig. 7012 Gruvlok Flange Adapter

can be used with the FTV Tri-Service

Valve. Installation is similar to the

installation of the Figure 7012 with

grooved pipe.

FTV-S (Straight) & FTV-A (Angle Body)

Tri-Service Valve

2

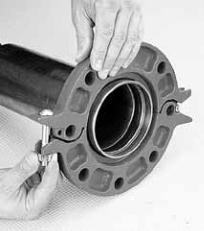

Loosen the nut on the latch bolt to the

end of the bolt thread. (It is not

necessary to remove the nut from the

latch bolt.) Swing the latch bolt out of the

slot. Open the Gruvlok Flange and place it

around the grooved tube with the key

section ftting into the groove. The fange

gasket cavity must face the tube end.

3

Swing the latch bolt back into the

slotted hole. Tighten the nut until the

fange halves make solid contact.

4

Check the gasket grade to verify that it

is properly suited for the intended

service. Lubricate the entire surface of the

gasket and the fange gasket cavity using

Gruvlok lubricant. Position the Gruvlok

Flange Gasket around the tube end and

press the gasket into the cavity between

the tube O.D. and the fange recess. The

gasket must be properly positioned as

shown in Step 5. Be careful that foreign

particles do not adhere to lubricated

surfaces.

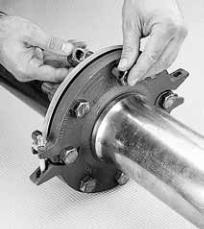

6

Align the Gruvlok Flange bolt holes

with the mating fange bolt holes.

Insert a standard bolt or stud through the

bolt hole, and thread a nut on hand tight.

Insert the next bolt or stud opposite the

frst and again thread the nut on hand

tight. Continue this procedure until all

holes have been ftted. (See illustration)

NOTE: Take care to assure that the gasket

lip is not bent backwards or pinched

between the two fanges.

7

Tighten the nuts evenly so that the

fange faces remain parallel and make

frm even contact around the entire

fange. Torque all bolts to required fange

joint torque levels.

1

START

Recommended Bolt Tightening Sequence

16

11

8

3

13

10

5

2

7

4

14

9

6

15

12

GL-2.10

Powered by FlippingBook Publisher