SEO Version

Valves & Accessories

Introduction

Couplings

Outlets

Fittings

Val

ves &

Accesso

ries

High

Pressure

Advanced Copper

Method (IPS)

DI-LOK

®

Nipples

Plain-End

Fittings

HDPE

Couplings

Sock-It

®

Fittings

Stainless

Steel Method

Roll

Groovers

Installation

& Assembly

Special

Coatings

Design

Services

Technical

Data

Master Format

3 Part Specs.

Pictorial

Index

CTS Copper

System

www.anvilintl.com

91

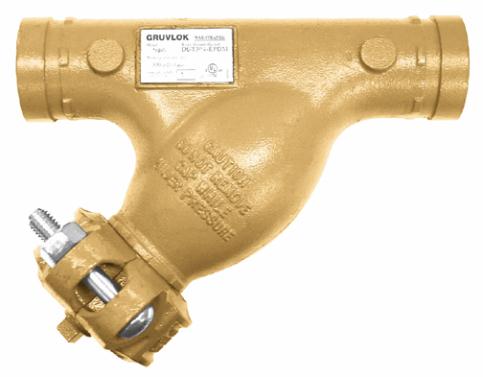

FIGURE 768 G GROOVED-END “WYE” STRAINER

Nominal

Size

O.D.

Working

Pressure

Dimensions

Cv

Values

Approx.

Wt. Each

A

B

C

D

Plug Size

In./DN(mm)

In./mm PSI/bar

In./mm In./mm In./mm In./mm

Lbs./Kg

2

2.375

300

9

3

⁄

4

7

1

⁄

8

4

9

⁄

16

1

⁄

2

59

9.3

50

60.3

20.7

248

192

116

12

4.2

2

1

⁄

2

2.875

300

10

3

⁄

4

7

13

⁄

16

4

13

⁄

16

1

⁄

2

92

13.2

65

73.0

20.7

273

211

122

12

6.0

3

3.500

300

11

3

⁄

4

8

11

⁄

16

5

1

⁄

16

1

162

18.0

80

88.9

20.7

298

231

129

25

8.2

4

4.500

300

14

1

⁄

4

10

5

⁄

8

6

5

⁄

8

1

284

26.4

100

114.3

20.7

362

281

168

25

12.0

5

5.563

300

16

1

⁄

2

13

10

3

⁄

16

1

410

46.4

125

141.3

20.7

419

330

258

25

22.0

6

6.625

300

18

1

⁄

2

14

1

⁄

16

8

5

⁄

8

1

1

⁄

2

770

70.4

150

168.3

20.7

470

357

219

38

32.0

8

8.625

300

24

17

7

⁄

8

11

3

⁄

16

1

1

⁄

2

1010 121.0

200

219.1

20.7

610

454

284

38

55.0

10

10.750 300

27

20

9

⁄

16

12

5

⁄

8

1

1

⁄

2

1800 182.6

250

273.1

20.7

686

522

320

38

83.0

12

12.750 300

30

24

14

3

⁄

8

1

1

⁄

2

2800 277.2

300

323.9

20.7

762

609

366

38

126.0

14

14.000 300

40

29

15

⁄

16

18

7

⁄

8

1

1

⁄

2

4600 418.0

350

355.6

20.7

1016

760

480

38

190.0

16

16.000 300

42

30

9

⁄

16

19

1

1

⁄

2

5800 495.0

400

406.4

20.7

1067

777

483

38

225.0

material specifications

MODEL 768G

Globally Sourced Grooved-end “Wye” Strainer

The Grooved-end Wye-Strainers are designed to strain debris

and foreign matter from piping systems and thus provide

inexpensive protection for costly pumps, meters and other

components. The Strainer can be installed quickly and easily

with two mechanical couplings and the straight fow through

design provides for lower pressure drop. This strainer features

a stainless steel screen that is secured with an end cap and

mechanical coupling. Cleaning and maintenance of the screen

can be accomplished easily by removing the coupling. The

Strainer is suitable for vertical and horizontal installations.

BODY:

Ductile iron ASTM A 536 Grade 65-45-12

END CAP:

Ductile iron ASTM A 536 Grade 65-45-12

SCREEN:

*

2" - 3" Type 304 Stainless Steel to ASTM A 240 -

1

⁄

16

" (1.6 mm) perforations

4" - 12" Type 304 Stainless Steel to ASTM A 240 -

1

⁄

8

" (3.2 mm) perforations

Other perforations are available upon request

COUPLING:

Ductile iron ASTM A 536 Grade 65-45-12

GASKET:

*

EPDM Temp range -40°F - +230°F (-40° to 110°C)

Nitrile Temperature range -20°F to 180°F (-29° to 82°C)

BLOW DOWN PORT:

2" & 2

1

⁄

2

":

1

⁄

2

" tapped with plug,

3" & 4": 1" tapped with plug,

6" - 12": 1

1

⁄

2

" tapped with plug

* Custom screens and/or gaskets are available upon request.

Strainer baskets need a routine maintenance program to maintain

effciency and to prevent excess pressure drop caused by a

clogged screen.

Not for use in copper systems.

• Pressure ratings listed are CWP (cold water pressure) or maximum working pressure within the service temperature

range of the gasket used in the coupling. This rating may occasionally differ from maximum working pressures listed

and/or approved by UL, ULC, and/or FM as testing conditions and test pipes differ.

• Maximum working pressure and end loads listed are total of internal and external pressures and loads based on Sch. 40

steel pipe with roll grooves to ANSI C606-97 specifcations.

• For one time feld test only the maximum joint working pressure may be increased 1

1

⁄

2

times the fgures shown.

• Warning: Piping systems must always be depressurized and drained before attempting disassembly and or removal of

any components.

Values for fow of water at +60°F (+16°C)

Where:

Q = Flow (GPM)

C

V

= fow coeffcient

∆

P = Pressure drop (PSI)

B

D

Plug Size

A

C

Screen

Removal

GL-2.10

Powered by FlippingBook Publisher