Page 9 - ThermoidPowerTransnmissionBeltsBrochure(HBDTHE-18770)

SEO Version

MAXIPOWERTM COGGED BELTS

Tensile members are engineered

to

resist fatigue and shock

loads. Cord and rubber are specially bonded

to

prevent

separation. And reinforcement layers on both sides of the

tensile member help improve cord stability.

Maxipower Cogged belts are constructed with neoprene

for excellent resistance to heat, oil, ozone, sunlight, weather

and aging. All belts are static conducting:

Maxipower Cogged belts are ideal for situations where

weight or sheave size is restricted. Where increased horse

power is required, Maxipower Cogged belts-used with

smaller sheaves-provide higher horsepower in

a

given

space when compared

to

Prime Mover.

With Maxipower Cogged belts, you can use sheaves

as

small

as

2.2"

in diameter-and achieve speed ratios up

to

13.65.

This lets you utilize high speed motors-which,

according

to

the National Electrical Manufacturers

Association, can mean

a

10% increase in energy efficiency.

The unique notched construction distributes bending

stress uniformly-and also provides superior heat dissipation.

In most installations, smaller diameter sheaves can be

used, permitting shorter center distances.

Maxipower Cogged belts are raw edge construction and

are cut

to

the precise dimensions

to

fit

the sheave groove.

As

a

result, you get maximum wedging action and reduced

chance of slippage.

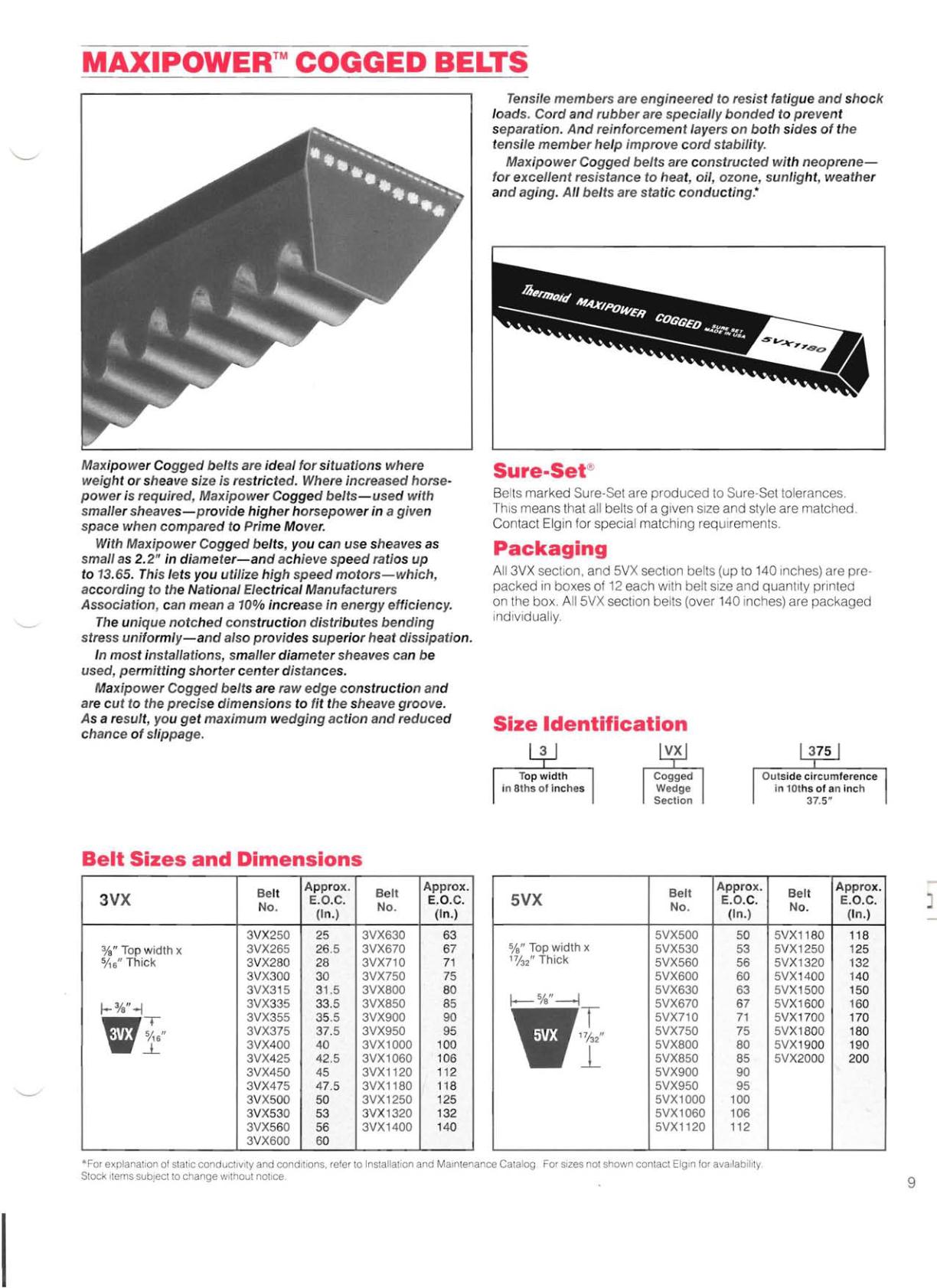

Belt Sizes and Dimensions

Sure-Set®

Belts marked Sure-Set are produced to Sure-Set tolerances.

ThiS means that all belts of a given size and style are matched

Contact Elgin for special matching requirements.

Packaging

All 3VX section, and 5VX section belts (up to

140

inches) are pre

packed in boxes of

12

each with belt size and quantity printed

on the box. AI15VX section belts (over

140

inches) are packaged

individually.

Size Identification

3VX

Belt

No.

Approx.

E.C.C.

(In.)

Belt

No.

Approx.

E.C.C.

(In.)

%"

Top width x

SA6"

Thick

I-

3fa"

-l

'l'f"

3VX250

3VX265

3VX280

3VX300

3VX315

3VX335

3VX355

3VX375

3VX400

3VX425

3VX450

3VX475

3VX500

3VX530

3VX560

3VX600

25

26.5

28

30

31.5

33.5

35.5

37.5

40

42.5

45

47.5

50

53

56

60

3VX630

3VX670

3VX710

3VX750

3VX800

3VX850

3VX900

3VX950

3VX1000

3VX1060

3VX1120

3VX1180

3VX1250

3VX1320

3VX1400

63

67

71

75

80

85

90

95

100

106

112

118

125

132

140

5VX

Belt

No.

Approx.

E.C.C.

(In.)

Belt

No.

Approx.

E.C.C.

(In.)

%"

Top width x

17/32 "

Thick

1---%"-1

WI

5VX500

5VX530

5VX560

5VX600

5VX630

5VX670

5VX710

5VX750

5VX800

5VX850

5VX900

5VX950

5VX1000

5VX1060

5VX1120

50

53

56

60

63

67

71

75

80

85

90

95

100

106

112

5VX1180

5VX1250

5VX1320

5VX1400

5VX1500

5VX1600

5VX1700

5VX1800

5VX1900

5VX2000

118

125

132

140

150

160

170

180

190

200

'For explanation of static conduclivity and conditions, refer to Installation and Maintenance Catalog For sizes not shown contact Elgin for availability.

Stock items subject to change without notice

9

Powered by FlippingBook Publisher