Page 164 - publication

SEO Version

gruvlok installation and assembly

www.anvilintl.com

164

FIG. 7005

Roughneck

®

Coupling

1

Make certain the pipe ends are free of indentations, projections, weld

splatter, or other imperfections which could prevent proper sealing of

the gasket.

2

Mark each pipe at a distance from the pipe end according to the pipe

run size. See Image 1 and the chart.

3

Check the gasket color code

to verify that the gasket

grade is properly suited for the

intended service. Apply a thin

coating of Gruvlok Lubricant to

the gasket lips and outside of the

gasket and slip the gasket over

one pipe. See Image 2. Make sure

the gasket does not overhang the

pipe end.

4

Align the second pipe and while holding the pipe in the butted

position slide the gasket back over the second pipe end. The gasket

should be equally spaced between the lines scribed on each pipe.

5

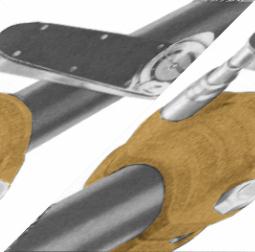

Place each half of the Roughneck coupling over the gasket, making sure

that the tongue on one housing half is aligned with the recess on the

other housing half. See Image 3.

6

Tighten the nuts alternately and uniformly until the required bolt

torque is reached. See Image 4 and chart for bolt torque.

7

Reinstallation after a disassembly will require that the threads on the

bolt and in the nut are clean and lubricated with a light oil.

NOTE:

Torque requirements must be met and housing halves must be

assembled with equal gaps between bolt pads.

Working pressure and end load are based on a properly assembled

Roughneck coupling with bolts fully torqued to the above specifcations,

on plain-end or beveled standard wall steel pipe and Gruvlok Plain-End

Fittings.

Roughneck Couplings are designed to be used on plain-end pipe and

Gruvlok Plain-End Fittings only. For externally coated pipe applications,

contact Gruvlok.

Not recommended for use on steel pipe with a hardness greater than 150

Brinell, plastic, HDPE, cast iron or other brittle pipe.

*Bolt torque ratings shown must be applied at installation.

Image 1

Image 2

Image 3

Image 4

Housing

Gasket

Pipe

Grippers

Pipe

Size

Distance

from pipe

end mark

Bolt Torque

Min.

Max

In./DN(mm)

In./mm Ft.-Lbs./N-m Ft.-Lbs./N-m

2 - 2

1

/

2

1

150 190

50-65

25.4

203

257

3 - 4

1

200 250

80-100

25.4

271

339

5 - 8

1

1

/

4

250 300

125-200

31.8

339

406

10

1

3

/

4

500 600

250

44.5

678

814

12

1

3

/

4

550 700

300

44.5

746

949

14 - 16 1

3

/

4

550 700

350-400

44.5

746

949

GL-2.10

Powered by FlippingBook Publisher