Page 166 - publication

SEO Version

gruvlok installation and assembly

www.anvilintl.com

166

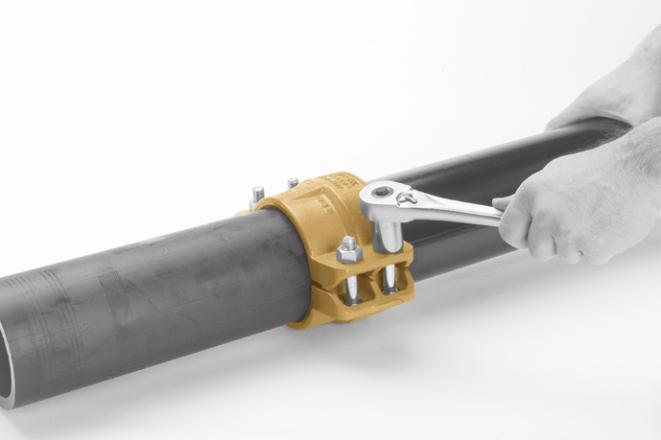

FIG. 7307

HDPE Transition Coupling

1

Make certain the HDPE pipe end is square

cut to

1

/

8

" maximum for the 2" to 4" and

5

/

32

"

maximum for the 6" and larger sizes. The steel

pipe must be grooved in accordance with

Gruvlok®Grooving Specifcations for Steel Pipe.

The pipe ends must be free of scratches,

indentations, projections or other imperfections,

which could prevent proper sealing of the

gasket.

2

Check to assure the gasket material is

acceptable for the intended service. The

Gasket color code is green for EPDM and

orange for Nitrile (Buna-N).

CAUTION:

Use

only Gruvlok Xtreme

TM

Lubricant. Gruvlok

Xtreme

TM

Lubricant contains silicone. If silicone

is unacceptable for the application contact

Gruvlok for the lubrication recommendation.

Apply a thin coating of Gruvlok Xtreme

TM

Lubricant to the gasket lips and outside surface

of the gasket.

3

Slip the gasket over one of the pipe ends.

Make sure the gasket does not overhang

the pipe end. Align the second pipe and while

holding it in the butted position, slide the

gasket back over the second pipe end. The

gasket must be positioned on the gasket seat

surface of the grooved steel pipe. Make sure the

gasket does not overhang into the pipe groove.

4

Place each half of the coupling housing over

the gasket, making sure the housing grooved

end is directed into the pipe groove.

5

Insert the bolts and secure the nuts

alternately and uniformly until the bolt pads

are in contact. Torque all bolts to the required

bolt torque levels. Refer to the Specifed Bolt

Torque Table. There is no gap between the bolt

pads and the bolt torque should be within the

range given when the coupling is properly

assembled. Alternate and even tightening of the

bolts will signifcantly reduce the torque needed

to close the gap at the pipe joint.

SPECIFIED BOLT TORQUE

Specifed bolt torque is for the oval neck track

bolts used on Gruvlok®couplings. The nuts must

be tightened alternately and evenly until fully

tightened.

CAUTION:

Use of an impact wrench

is not recommended because the torque output

can vary signifcantly due to many variables

including air pressure supply, battery strength

and operational variations.

CAUTION:

Proper torquing of coupling bolts is required to

obtain specifed performance.

Over torquing the bolts may

result in damage to the bolt and/or casting which could

result in pipe joint separation.

Under torquing the bolts may

result in lower pressure retention capabilities, lower bend

load capabilities, joint leakage and pipe joint separation.

Pipe joint separation may result in signifcant property

damage and serious injury.

FIG. 7307 SPECIFIED BOLT TORQUE

Coupling Bolts

Minimum Maximum

In.

Ft.-Lbs./N-m

Ft.-Lbs./N-m

1

/

2

X

2

3

/

8

80

100

110

150

1

/

2

X

3

80

100

110

150

5

/

8

X

3

1

/

2

100

130

135

175

7

/

8

X

5

1

/

2

180

220

245

300

GL-2.10

Powered by FlippingBook Publisher