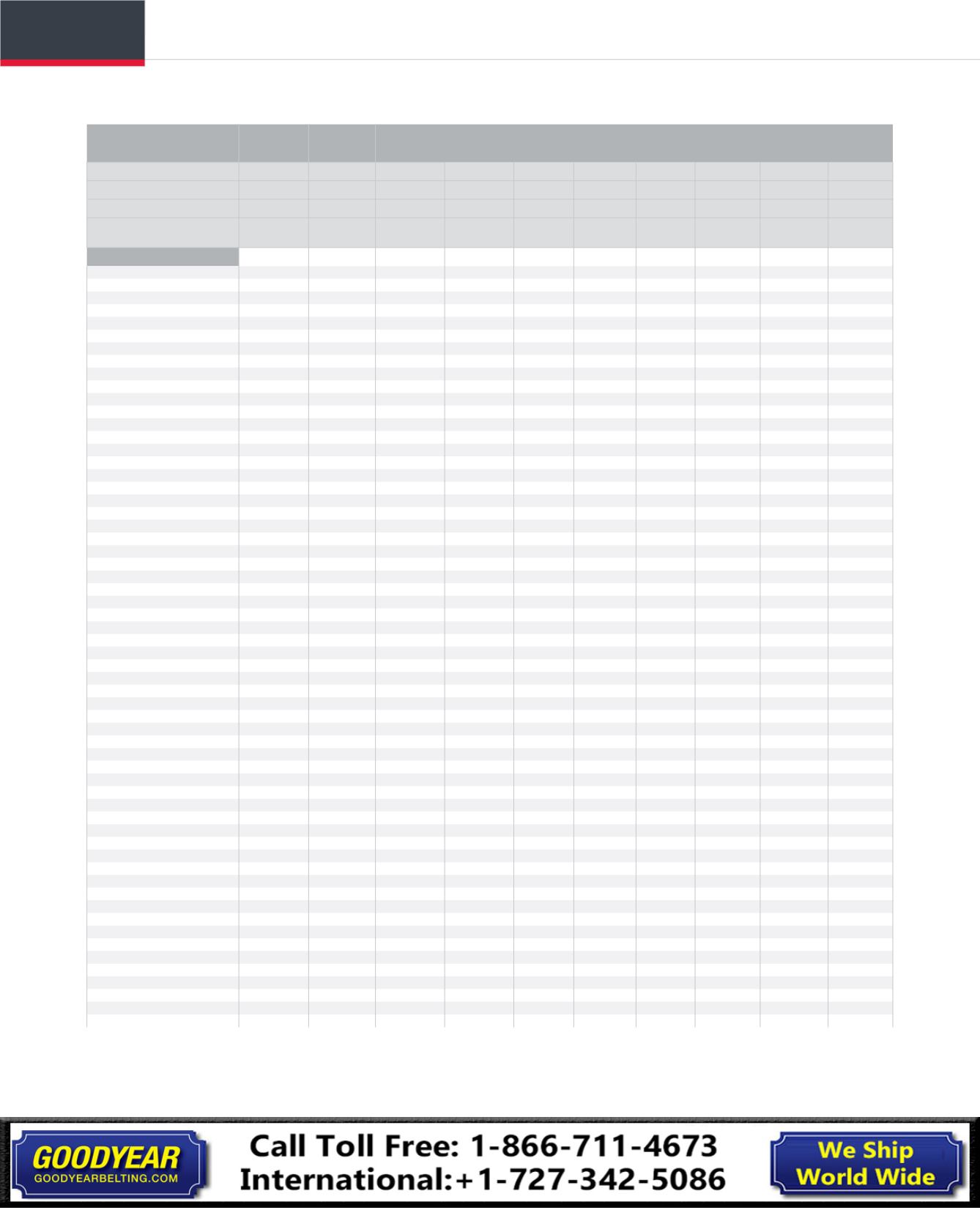

CHEMICAL RESISTANCE

REFERENCE

CHARTS

PVC

Poly Vinyl

Chloride

RAV

Rubber &

Vinyl

URETHANE SBR

NBR

MOR

SOR

EPDM BUTYL

NATURAL

RUBBER

Temperature Range

0°F to 180°F -20°F to 180°F -20°F to 180°F -25°F to 250°F 0°F to 250°F -20°F to 200°F -10°Fto200°F -20°F to 400°F -65°F to 300°F -40°F to 200°F

Abrasion Resistance

Good

Good

Excellent

Excellent

Good

Good

Good

Good

Fair

Excellent

Cut/Gouge Resistance

Good

Good

Excellent

Good

Good

Good

Good

Good

Good

Excellent

Oil Resistance

Good

Excellent

Excellent

Not

Recommended

Excellent

Good

Excellent

Not

Recommended

Not

Recommended

Not

Recommended

CHEMICAL

Rapeseed Oil

NR

U

G

NR

G

F

G

E

E

NR

Salicylic Acid

E

E

E

G

E

G

E

E

E

E

Salt Water

E

E

E

E

E

E

E

E

E

E

Sewage

F

F

E

NR

E

F

E

F

NR

NR

Shellac (flakes)

E

E

E

E

E

E

E

E

E

E

Silicone Oil

F

E

E

F

E

G

E

G

E

F

Soap Solutions

E

U

E

G

E

E

E

E

E

G

Soda Ash

E

E

E

E

E

E

E

E

E

E

Sodium Bicarbonate

E

E

E

E

E

E

E

E

E

E

Sodium Bisulfate

E

E

E

G

E

G

E

E

E

E

Sodium Chloride

E

E

E

E

E

E

E

E

E

E

Sodium Hydroxide (dil)

E

E

E

E

G

E

G

E

E

E

Sodium Hypochlorite

E

E

E

F

G

F

G

G

G

F

Sodium Nitrate

E

E

E

G

G

G

G

E

E

G

Sodium Perborate

E

U

E

G

G

G

G

E

E

G

Sodium Peroxide

E

E

E

G

G

G

G

E

E

G

Sodium Phosphates

E

E

E

E

E

E

E

E

E

E

Sodium Silicate

E

E

E

E

E

E

E

E

E

E

Sodium Sulfate

E

E

E

G

E

E

E

E

E

G

Sodium Sulfide

E

E

E

F

NR

F

F

G

E

F

Sodium Thiosulfate

E

E

E

G

G

G

G

E

G

G

Sodium Chloride

E

E

E

E

E

E

E

E

E

E

Soybean Oil

F

E

U

F

E

U

U

U

U

U

Stearic Acid

G

U

E

F

F

F

F

F

E

F

Sugar Beets

E

E

E

E

E

E

E

E

F

E

Sugar Cane

E

E

E

E

E

E

E

E

E

E

Sugar Syrup

E

E

E

E

E

E

E

E

E

E

Sulfur

E

E

E

NR

NR

NR

NR

E

E

NR

Sulfuric Acid (dil)

E

E

E

F

NR

F

F

G

E

F

Sulfurous Acid

E

E

E

F

NR

F

F

G

G

F

Sunlight

E

E

E

G

G

G

G

G

G

G

Tannic Acid

E

E

E

G

E

G

E

E

E

G

Tanning Liquor

F

U

G

NR

G

F

G

NR

E

NR

Tar, Bituminous

F

E

E

NR

E

F

G

NR

NR

NR

Tartaric Acid

E

E

E

G

E

G

E

G

NR

G

Tetrachloroethylene

NR

NR

NR

NR

NR

NR

NR

NR

G

NR

Touene (Toluol)

NR

F

NR

NR

F

NR

F

NR

NR

NR

Transformer Oil

F

U

G

NR

E

F

E

NR

NR

NR

Transmission-Type A

F

U

G

NR

E

G

E

NR

NR

NR

Trichloroethylene

NR

NR

NR

NR

F

NR

NR

NR

NR

NR

Trichloroethane

NR

NR

NR

NR

NR

NR

NR

NR

NR

NR

Tricresyl Phosphate

F

U

NR

NR

NR

NR

NR

F

E

NR

Trisodium Phosphate

E

U

E

E

E

E

E

E

E

E

Tung Oil

F

U

G

NR

E

G

E

F

F

NR

Turpentine

NR

F

NR

NR

R

G

E

NR

NR

NR

Ultra-Violet (moderate exposure)

E

E

E

G

G

G

G

G

E

F

Urea

E

E

E

E

E

E

E

E

E

E

Urine

E

E

G

G

G

G

G

G

G

G

Vegetable Oils

NR

E

G

NR

E

G

E

F

F

NR

Vinegar

E

E

E

G

G

G

G

E

E

G

Water

E

E

E

E

E

E

E

E

E

E

Whiskey

G

G

G

E

E

E

E

E

E

E

Wines

G

G

G

E

E

E

E

E

E

E

White Pine Oil

F

U

G

NR

E

G

E

NR

NR

NR

White Oil

F

U

E

NR

E

G

E

NR

NR

NR

Wood Oil

F

E

E

NR

E

G

E

NR

NR

NR

Wood Chips

G

G

E

F

E

G

E

NR

NR

F

Xylene-Attacks Nylon

NR

NR

NR

NR

NR

NR

NR

NR

NR

NR

Zinc Chloride

E

E

E

E

E

E

E

E

E

E

Zinc Sulphate

E

E

E

G

E

E

E

E

E

G

PVC

— Poly Vinyl Chloride (PVC) is biologically and chemically resistant. PVC can be formulated

to meet fire resistant and anti-static requirements.

RAV

— Rubber and Vinyl (RAV), also known as RMV, is a refined PVC formulation. If offers high

resistance to fats, oils and chemicals. It is a popular compound for use in food applications.

Urethane

— Urethane is a good choice for rough and/or oily applications. It enjoys excellent

abrasion and oil resistance and/or oily applications. It enjoys excellent abrasion and oil resistance.

SBR

— Styrene Butadiene Rubber (SBR) is also known as RMA Grade II rubber. Its abrasion

resistance makes this compound popular for belting in the Aggregate Industry and package

handling applications, among others. It has good resistance to the elements, ozone and sunlight

but poor oil resistance.

NBR

— Butadiene Acrylonitrile, also called Nitrile or Buna-N or NBR, gives resistance to oil, heat

and grease. Examples: 1-2002, 1-6003

MOR

— MOR stands for Moderate Oil Resistance. This compound performs well in wood,

agriculture and light industrial applications where limited oils are present.

SOR

— Super Oil Resistance (SOR) engenders extra oil resistance. It is used in high oil

applications such as asphalt manufacture.

EPDM

— Ethylene Propylene Diene Methylene Tripolymer (EPDM) is a formulation designed for

extreme temperature, up to 350°F for fines and 400°F for lumps.

Butyl

— Isobutylene Isoprene (Butyl) has very good temperature resistance. It can withstand

environments from -65°F to 300°F. It is popular in food applications but has limited abrasion

resistance.

Natural Rubber

— Natural Rubber or Polyisoprene exhibits abrasion, gouge and cut resistance. It

is generally used in non-marking belts.