Expansion Joints

Javascript DHTML Drop Down Menu Powered by dhtml-menu-builder.com

|

Eccentric Reducer Expansion Joints Series RE

The PROCO Series RE-221 Rubber Eccentric Reducer Expansion Joint, often called a “Taper”, serves as a reducing element to transition from one pipe size to another. Eccentric in design, the rubber expansion joint body tapers on one side transitioning two different flange sizes. Eccentric Reducer Expansion Joints are often located on the suction side of a pump to reduce cavitation. The PROCO Rubber Eccentric Reducer is engineered to replace metallic or rubber-lined reducers used to provide unequal diameter connections of: piping and/or operating equipment applications such as: Pumps, Chillers, Cooling Towers, Compressors, Blowers, Fans, Absorption Machines, etc. Installed next to mechanical equipment or between the anchor points of a piping system, specify the PROCO Series RE-221 to: (1) Absorb Pipe Movement/Stress, (2) Reduce System Noise, (3) Isolate Mechanical Vibration, (4) Compensate Alignment/Offset, (5) Eliminate Electrolysis, (6) Protect Against Start-up/Surge Forces. The PROCO Series RE-221 is engineered for tough, demanding, industrial and commercial applications, as found in: Air Conditioning-Heating and Ventilating Systems, Chemical-Petrochemical and Industrial Process Piping Systems, Power Generating Plants, Steel Mills, Marine Services, Pulp/Paper Systems, Water-Wastewater- Sewage and Pollution Control Systems, where metallic reducers used in conjunction with metal hose or expansion joints may have been previously used or specified. Our history in manufacture of expansion joint products dates back to 1930. PROCO Products is a member of the Rubber Expansion Joint Division, Fluid Sealing Association. When a rubber expansion joint is needed to solve a piping system problem, call PROCO. Traditional design when using a metallic reducer incorporates the use of a flexible element such as an expansion joint or metal hose to absorb the vibrations and movements of the system. The PROCO Series RE-221 Reducer combines the basic shape and dimensions of the metal reducer and the movement-sound reduction vibration-absorbing features of a flexible element into one unit. Here are some of the many advantages:

• Less System Installation Space:

The PROCO RE-221 replaces a metal reducer and a flexible element. Thus less space is required and valves of other equipment can be more conveniently located.

• Less Installation Cost:

The PROCO RE-221 costs less then the metal reducer and flexible element that are replaced. Additionally, standard joints (as listed in Table 1 and the “stock” section in Table 2) can be shipped same day as order placement.

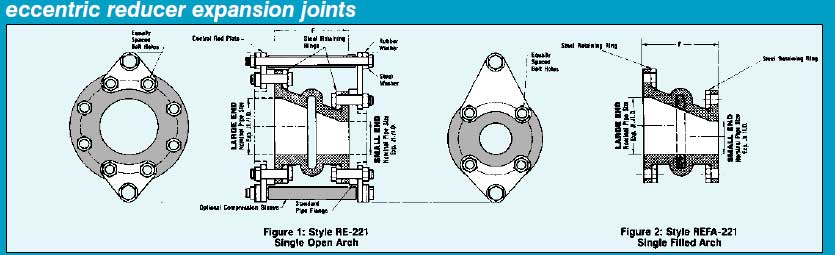

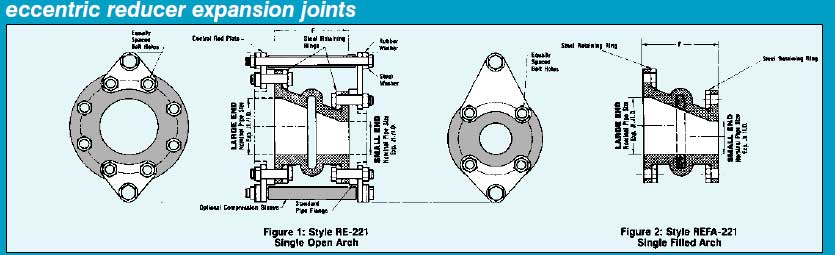

Engineered For Your Application: The PROCO Eccentric Reducer materials consist of rubber and fabric which are formed and cured in a heated compression mold using an exclusive high-pressure press. The thick outer-cover and interior-tube are of an elastomer especially compounded to satisfy the Chemical-Temperature requirement of your application. Available styles include:

• Style RE-221:

Features one Open Arch for maximum movement, and good noise-vibration control. Our most popular style. (See Figure 1)

• Style-REFA-221:

Features one Filled Arch, is generally specified for slurry or abrasive services. Provides noise and vibration control but less movement than Style RE-221. (See Figure 2)

Absorbs Pipe-Wall And Fluid-Borne Noise. The PROCO quiet-operating Series RE-221 is a replacement for “sound transmitting” metallic reducers. Pipe-Wall sound loses energy and is absorbed as the noise carried by the piping enters and exits the rubber section. Fluid-borne noise is absorbed by the volumetric expansion (breathing) of the connector. This action cushions water hammer, and smooths out pumping impulses.

Isolates Vibrations And Motion. Vibration originating from mechanical equipment is absorbed by the PROCO Series RE-221. Rubber connectors should be installed right after and ahead of the equipment generating the vibration, thus isolating the equipment. Most machinery vibrates in a radial direction from the main shaft. For optimum performance the PROCO connector should be installed horizontally and parallel to this shaft. Vertical and perpendicular installations are also acceptable as the PROCO Reducer will accept both axial and lateral movements and vibration. Installations of the Series RE-221 in a system enables isolated equipment to move freely on its vibration mountings. Note: For maximum vibration transmission reduction, the piping section beyond the rubber connector must be anchored or sufficiently rigid.

Chemical Or Abrasive Service Capability At Minimal Cost. Expensive, exotic metal or rubber lined reducers for chemical service can be replaced with the PROCO Rubber Reducer. Fabricated with low-cost chemical resistant elastomers such as: Chlorobutyl, EPDM, Hypalon, Neoprene and Nitrile; insures a rubber connector compatible with the fluid being pumped or piped. (See Table 1) Our Neoprene, Natural/Gum and filled arch products should be specified when handling abrasive slurries. Use the PROCO “Chemical to Elastomer Guide” to specify an elastomer for your requirement.

Reduces System Stress And Strain/Compensate For Misalignment. Rigid attachment of piping to critical or mechanical equipment can produce excessive loading. Thermal or mechanically created strain-stress-shock are cushioned and absorbed with the installation of a flexible low “force-to-deflect” PROCO Rubber Reducer. The PROCO Style RE- 221 adds a flexible component that is automatically self-correcting for misalignment created by structural movements caused by setting, expansion or ground shifts.

Flange And Retaining Ring Drilling. All PROCO rings are coated to prevent corrosion and dimensionally drilled to ANSI 125/150# standards. In accordance with ANSI, all bolt hole pairs are “straddle” the center line. Hole drilling on center line, other drilling standards or materials such as: 304 or 316 Stainless and Bronze are available on special order.

Less Turbulence Or Material Entrapment. The molded integral flange of the PROCO Rubber Reducer joins the body at a true 90 degree angle. Our product will install snug against the mating pipe flange without voids. Because this flange-body angle is difficult to form, many competitors severely radius this edge angle. The resulting void can create flow turbulence, allow for material entrapment and/or bacteria growth. Avoid these problems by specifying PROCO. Exclusive Sealing Bead Means A Quick Seal. We have built an “O-Ring” on each flange-face of the Series RE-221. Available only from PROCO, our product seals faster with less torque at installation and less long-term maintenance. For exclusive design features, specify PROCO. High Pressure With Full Safety Factors. We have assigned conservative pressure ratings to the Series RE-221. However, the ratings meet or exceed the requirements of the Rubber Expansion Joint Division, Fluid Sealing Association, for Series A, B, and C. More importantly, our conservative ratings are fully tested and based on a minimum four-toone safety factor. With competitive products the safety factor is often calculated or unknown. For pressure protection, specify PROCO.

|

Concentric Reducer Expansion Joints Series RC

The PROCO Series RE-221 Rubber Eccentric Reducer Expansion Joint, often called a “Taper”, serves as a reducing element to transition from one pipe size to another. Eccentric in design, the rubber expansion joint body tapers on one side transitioning two different flange sizes. Eccentric Reducer Expansion Joints are often located on the suction side of a pump to reduce cavitation. The PROCO Rubber Eccentric Reducer is engineered to replace metallic or rubber-lined reducers used to provide unequal diameter connections of: piping and/or operating equipment applications such as: Pumps, Chillers, Cooling Towers, Compressors, Blowers, Fans, Absorption Machines, etc. Installed next to mechanical equipment or between the anchor points of a piping system, specify the PROCO Series RE-221 to: (1) Absorb Pipe Movement/Stress, (2) Reduce System Noise, (3) Isolate Mechanical Vibration, (4) Compensate Alignment/Offset, (5) Eliminate Electrolysis, (6) Protect Against Start-up/Surge Forces. The PROCO Series RE-221 is engineered for tough, demanding, industrial and commercial applications, as found in: Air Conditioning-Heating and Ventilating Systems, Chemical-Petrochemical and Industrial Process Piping Systems, Power Generating Plants, Steel Mills, Marine Services, Pulp/Paper Systems, Water-Wastewater- Sewage and Pollution Control Systems, where metallic reducers used in conjunction with metal hose or expansion joints may have been previously used or specified. Our history in manufacture of expansion joint products dates back to 1930. PROCO Products is a member of the Rubber Expansion Joint Division, Fluid Sealing Association. When a rubber expansion joint is needed to solve a piping system problem, call PROCO. Traditional design when using a metallic reducer incorporates the use of a flexible element such as an expansion joint or metal hose to absorb the vibrations and movements of the system. The PROCO Series RE-221 Reducer combines the basic shape and dimensions of the metal reducer and the movement-sound reduction vibration-absorbing features of a flexible element into one unit. Here are some of the many advantages:

• Less System Installation Space: The PROCO RE-221 replaces a metal reducer and a flexible element. Thus less space is required and valves of other equipment can be more conveniently located.

• Less Installation Cost: The PROCO RE-221 costs less then the metal reducer and flexible element that are replaced. Additionally, standard joints (as listed in Table 1 and the “stock” section in Table 2) can be shipped same day as order placement. Engineered For Your Application: The PROCO Eccentric Reducer materials consist of rubber and fabric which are formed and cured in a heated compression mold using an exclusive high-pressure press. The thick outer-cover and interior-tube are of an elastomer especially compounded to satisfy the Chemical-Temperature requirement of your application. Available styles include:

• Style RE-221: Features one Open Arch for maximum movement, and good noise-vibration control. Our most popular style. (See Figure 1)

• Style-REFA-221: Features one Filled Arch, is generally specified for slurry or abrasive services. Provides noise and vibration control but less movement than Style RE-221. (See Figure 2) Absorbs Pipe-Wall And Fluid-Borne Noise. The PROCO quiet-operating Series RE-221 is a replacement for “sound transmitting” metallic reducers. Pipe-Wall sound loses energy and is absorbed as the noise carried by the piping enters and exits the rubber section. Fluid-borne noise is absorbed by the volumetric expansion (breathing) of the connector. This action cushions water hammer, and smooths out pumping impulses. Isolates Vibrations And Motion. Vibration originating from mechanical equipment is absorbed by the PROCO Series RE-221. Rubber connectors should be installed right after and ahead of the equipment generating the vibration, thus isolating the equipment. Most machinery vibrates in a radial direction from the main shaft. For optimum performance the PROCO connector should be installed horizontally and parallel to this shaft. Vertical and perpendicular installations are also acceptable as the PROCO Reducer will accept both axial and lateral movements and vibration. Installations of the Series RE-221 in a system enables isolated equipment to move freely on its vibration mountings. Note: For maximum vibration transmission reduction, the piping section beyond the rubber connector must be anchored or sufficiently rigid. Chemical Or Abrasive Service Capability At Minimal Cost. Expensive, exotic metal or rubber lined reducers for chemical service can be replaced with the PROCO Rubber Reducer. Fabricated with low-cost chemical resistant elastomers such as: Chlorobutyl, EPDM, Hypalon, Neoprene and Nitrile; insures a rubber connector compatible with the fluid being pumped or piped. (See Table 1) Our Neoprene, Natural/Gum and filled arch products should be specified when handling abrasive slurries. Use the PROCO “Chemical to Elastomer Guide” to specify an elastomer for your requirement. Reduces System Stress And Strain/Compensate For Misalignment. Rigid attachment of piping to critical or mechanical equipment can produce excessive loading. Thermal or mechanically created strain-stress-shock are cushioned and absorbed with the installation of a flexible low “force-to-deflect” PROCO Rubber Reducer. The PROCO Style RE- 221 adds a flexible component that is automatically self-correcting for misalignment created by structural movements caused by setting, expansion or ground shifts. Flange And Retaining Ring Drilling. All PROCO rings are coated to prevent corrosion and dimensionally drilled to ANSI 125/150# standards. In accordance with ANSI, all bolt hole pairs are “straddle” the center line. Hole drilling on center line, other drilling standards or materials such as: 304 or 316 Stainless and Bronze are available on special order. Less Turbulence Or Material Entrapment. The molded integral flange of the PROCO Rubber Reducer joins the body at a true 90 degree angle. Our product will install snug against the mating pipe flange without voids. Because this flange-body angle is difficult to form, many competitors severely radius this edge angle. The resulting void can create flow turbulence, allow for material entrapment and/or bacteria growth. Avoid these problems by specifying PROCO. Exclusive Sealing Bead Means A Quick Seal. We have built an “O-Ring” on each flange-face of the Series RE-221. Available only from PROCO, our product seals faster with less torque at installation and less long-term maintenance. For exclusive design features, specify PROCO. High Pressure With Full Safety Factors. We have assigned conservative pressure ratings to the Series RE-221. However, the ratings meet or exceed the requirements of the Rubber Expansion Joint Division, Fluid Sealing Association, for Series A, B, and C. More importantly, our conservative ratings are fully tested and based on a minimum four-toone safety factor. With competitive products the safety factor is often calculated or unknown. For pressure protection, specify PROCO.

|

Add to Quote Cart

Applications

Expansion Joints is used in industrial transfer, handling, and support operations where reliable product performance and practical sourcing support are required.

Materials Overview

Material selection varies by media, environment, fitting interface, and service conditions. Existing product details above remain the primary source for specifications.

Selection Guidance

Match product configuration to your operating media, routing constraints, connection standards, and maintenance expectations. Use the quote cart to submit project requirements.

Installation and Maintenance Notes

Follow manufacturer handling practices, inspect components before installation, verify connection compatibility, and schedule routine inspections based on your service cycle.

Industries Served

Industrial manufacturing, processing, utilities, construction, transportation, and maintenance operations.

Technical Specifications

| Existing Technical Claim (Verbatim) |

|---|

| 221: Features one Open Arch for maximum movement, and good noise-vibration control. |

| 2) Absorbs Pipe-Wall And Fluid-Borne Noise. |

Related Products

FAQ

- How do I select the right Expansion Joints?

- Selection depends on your operating conditions, media, fittings, routing, and service goals. Submit a quote request for application-specific guidance.

- Can I request custom options for Expansion Joints?

- Custom manufacturing and configuration support are available on request. Include project details with your quote cart submission.

- Do you provide volume pricing?

- Bulk and volume pricing are available upon request. Add required quantities to the quote cart for review.

- How quickly can I receive a quote?

- Our team provides fast quote turnaround for standard and custom industrial product requests.

Trust and Support

- Fast quote turnaround

- Custom manufacturing available

- Bulk and volume pricing upon request

- Sales engineer assistance

Back to Top 100 Products

|