Flexitallic Spiralwound Gaskets

Quote Cart: 0 item(s) | View Quote Cart

|

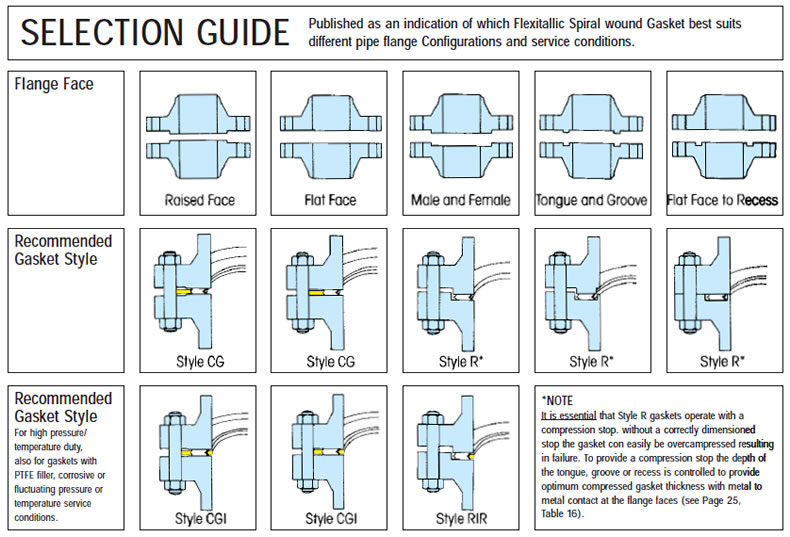

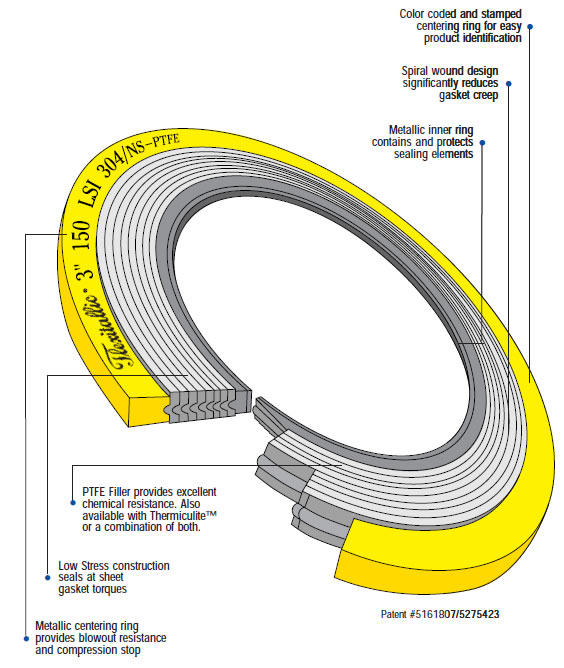

| Introduction FIRST AND FOREMOST The concept of spiral wound gasket construction was originated by Flexitallic in 1912, inaugurating the beginning of a new era in safe. effective sealing. The primary purpose for this development was the increasingly severe temperatures and pressures used by U.S. refinery operators in the first half of the century. The necessity for a gasket to have the ability to recover cannot be over emphasized. The effects of pressure and temperature fluctuations, the temperature differential across the flange face, together with bolt stress relaxation and creep, demand a gasket with adequate flexibility and recovery to maintain a seal even under these varying service conditions. The Flexitallic Spiral Wound Gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and pressure in flanged joints and similar assemblies and against virtually every known corrosive and toxic media. This publication is designed to facilitate the specification and ordering of standard Flexitallic Spiral Wound Gaskels. Dimensional data for the basic styles - Style CG, Style CGI, Style Rand Style RIR are detailed on respective tables. |

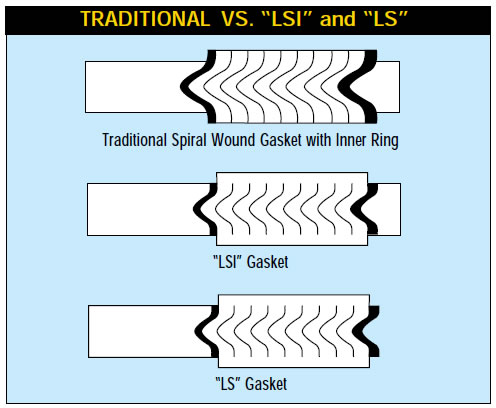

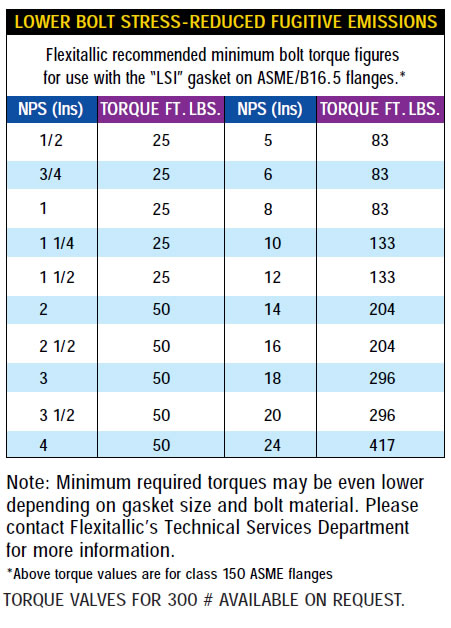

STYLE LS & LSI LOW STRESS RANGE OF SPIRAL WOUND GASKETS Tho LS gasket offers the same high integrity seal associated with the spiral wound gasket however the LS and LSI has been designed in such a way that compresion and sealing requirements are achieved under very low seating stresses. These gaskets are intended for use on class 150 and 300 applications where customers traditionally do not use spiral wound gaskets due to concerns about exceeding allowable design stresses.

Tho traditional spiral wound gasket has its steel windings protruding above the compression stop; this requires a significant loading stress to compress the gasket to its optimum operating thickness. The LS and LSI gaskets have only soft Flexicarb or PTFE filler protruding above metal windings and guide ring; therefore as the gasket is compressed, the Flexicarb, Thermiculite 836 or PRFE filler is readily compressed thus productin the sealing mechanism at an earlier stage as compated to the conventionally manufactured sprial wound gasket.

|

Add to Quote Cart

Applications

Flexitallic Spiralwound Gaskets is used in industrial transfer, handling, and support operations where reliable product performance and practical sourcing support are required.

Materials Overview

Material selection varies by media, environment, fitting interface, and service conditions. Existing product details above remain the primary source for specifications.

Selection Guidance

Match product configuration to your operating media, routing constraints, connection standards, and maintenance expectations. Use the quote cart to submit project requirements.

Installation and Maintenance Notes

Follow manufacturer handling practices, inspect components before installation, verify connection compatibility, and schedule routine inspections based on your service cycle.

Industries Served

Industrial manufacturing, processing, utilities, construction, transportation, and maintenance operations.

Related Products

- Flexaust Ducting Hose

- Flexco Belt Fasteners

- Flexdock Hose

- Flexsteel Hoses

- Flextra Hoses

- Flexwing Hose

FAQ

- How do I select the right Flexitallic Spiralwound Gaskets?

- Selection depends on your operating conditions, media, fittings, routing, and service goals. Submit a quote request for application-specific guidance.

- Can I request custom options for Flexitallic Spiralwound Gaskets?

- Custom manufacturing and configuration support are available on request. Include project details with your quote cart submission.

- Do you provide volume pricing?

- Bulk and volume pricing are available upon request. Add required quantities to the quote cart for review.

- How quickly can I receive a quote?

- Our team provides fast quote turnaround for standard and custom industrial product requests.

Trust and Support

- Fast quote turnaround

- Custom manufacturing available

- Bulk and volume pricing upon request

- Sales engineer assistance