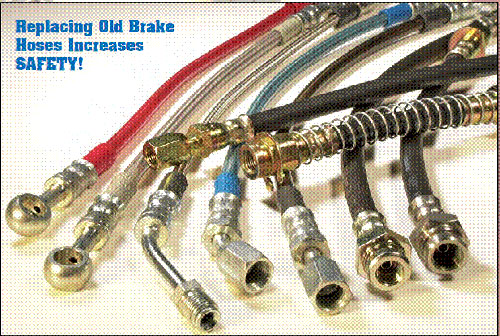

BrakeQuip Brake and Clutch Hose Assemblies

Quote Cart: 0 item(s) | View Quote Cart

|

|

Faulty Brake Hoses Are an Invisible Safety Hazard Generally. all brake hoses on a vehicle |

Experience the Convenience of • All hoses compliant to SAE J1401 |

Handy Tips & Information The most effective way to look for faulty brake hoses is to check them when they are under extreme pressure. Visual Inspection of Hose and Installation Things to look for. Troubleshooting Problems Associated with Brake Hoses 1. LOW OR SPONGY PEDAL Determlning the Length of a Hose Except for a hose with a banjo fitting, all hose lengths are determined by measuring the extreme points. When measuring the length of a hose with a |

|

Add to Quote Cart

Applications

BrakeQuip Brake and Clutch Hose Assemblies is used in industrial transfer, handling, and support operations where reliable product performance and practical sourcing support are required.

Materials Overview

Material selection varies by media, environment, fitting interface, and service conditions. Existing product details above remain the primary source for specifications.

Selection Guidance

Match product configuration to your operating media, routing constraints, connection standards, and maintenance expectations. Use the quote cart to submit project requirements.

Installation and Maintenance Notes

Follow manufacturer handling practices, inspect components before installation, verify connection compatibility, and schedule routine inspections based on your service cycle.

Industries Served

Industrial manufacturing, processing, utilities, construction, transportation, and maintenance operations.

Related Products

- ARVAC™SW abrasion-resistant suction hose

- Acculink Belt

- Acme thread Sanitary Hose Couplings

- Ag Spray Hose

- Air Hose

- Aircraft Refueling Hose

FAQ

- How do I select the right BrakeQuip Brake and Clutch Hose Assemblies?

- Selection depends on your operating conditions, media, fittings, routing, and service goals. Submit a quote request for application-specific guidance.

- Can I request custom options for BrakeQuip Brake and Clutch Hose Assemblies?

- Custom manufacturing and configuration support are available on request. Include project details with your quote cart submission.

- Do you provide volume pricing?

- Bulk and volume pricing are available upon request. Add required quantities to the quote cart for review.

- How quickly can I receive a quote?

- Our team provides fast quote turnaround for standard and custom industrial product requests.

Trust and Support

- Fast quote turnaround

- Custom manufacturing available

- Bulk and volume pricing upon request

- Sales engineer assistance