Plylon Plus Belts

Javascript DHTML Drop Down Menu Powered by dhtml-menu-builder.com

|

|

|

Plylon Plus® Belts

Plylon Plus® is our premium all-purpose fabric conveyor belt construction that can be used in a variety of industries and applications with most of our exclusive ContiTech rubber cover compounds. |

Markets

- Aggregate

- Baggage handling

- Bulk handling terminal

- Cement

- Coal

- Crushed stone

- Foundry

- Grain

- Hard rock

- Package handling

- Power generation

- Pulp and paper

- Sand and gravel

- Steel production

- Wood products

|

Applications

- Coal prep plant

- Log debarkers

- Log decks

- Mainlines

- Pit belts

- Primary crushers

- Secondary crushers

- Ship unloaders

- Stacker conveyors

- Trash and recycling

- Block plants

- Load out

- Radial stackers

- Ready mix

- Wash plant

|

Cover Compounds

- 6740 A

- Defender® Plus

- FR-2G

- FRAR-2G

- FRORS-2G

- HT Nitrile

- Protector

- Stacker®

- Survivor®

- Survivor® Plus

|

|

Get a lower cost-per-ton conveyed. Tension Range: 220 to 1800 PIW

|

Features & Benefits

|

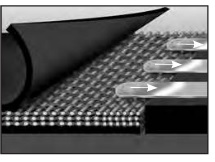

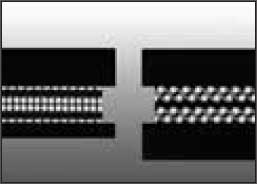

Excellent fastener holding retention High strength fill cords enhance mechanical fastener holding ability and resist fastener pull-out for reliable performance and increased uptime.

|

|

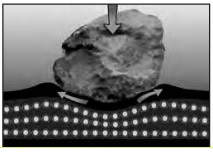

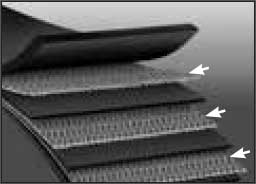

Excellent rip, tear and impact resistance Specially designed crimped warp cords straighten on impact and then recover their original shape. This enables the fabric to absorb greater impact loads and resist tearing for long-lasting durability and a lower cost-per-ton conveyed.

|

|

High ultimate strength

Plylon Plus® withstands severe tension spikes at start up, retains mechanical fasteners and withstands continuous flexing around pulleys. This higher ultimate strength makes a critical difference in abusive operating conditions.

|

|

Reduced stretch

The combination of fabric design and dip process provides lower elasticity and permanent elongation on all specifications. This minimizes take-up concerns and reduces the number of splices at break-in. Contact your local Sales Representative to calculate permanent and elastic elongation requirements for your specific systems.

|

|

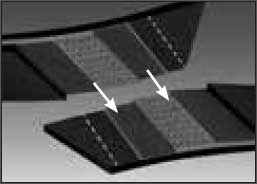

Standard bias step splices

A quick and effective technique, step splices greatly reduce downtime and are recognized throughout the industry as the standard. The vulcanized splice in Plylon Plus® retains 100% of belt tension rating during all running conditions.

|

|

Variety of cover compounds and cover gauges

Protect your product with the proper compound and cover gauge for the application. Plylon Plus® has the flexibility to customize a belt to your application.

|

|

Variety of fabric carcasses

Choose from a selection of carcasses that provide outstanding strength, adhesion, impact absorption and other properties. These include fabric carcasses from 220 to 1800 PIW.

|

|

Plylon Plus® Conveyor Belt Data

|

Plylon Plus 800/4 |

Plylon Plus 900/2 |

Plylon Plus 1000/4 |

Plylon Plus 1000/5 |

Plylon Plus 1200/6 |

Plylon Plus 1250/5 |

Plylon Plus 1350/3 |

Plylon Plus 1800/4 |

| # of Plies |

4 |

2 |

4 |

5 |

6 |

5 |

3 |

4 |

| Fabric Type* |

P/P |

P/N |

P/P |

P/P |

P/P |

P/P |

P/N |

P/N

|

| Average Permanent Elongation (%)** |

0.8 |

1.5 |

1.0 |

0.80 |

0.80 |

1.0 |

1.5 |

1.5

|

| Recommended Fastener Plate |

BR-14 |

NR |

NR |

NR |

NR |

NR |

NR |

NR

|

| Hinge |

R6 |

RAR8 |

RAR8 |

RAR8 |

RAR8 |

RAR8 |

NR |

NR

|

| Hinge |

U37/U37A |

U38A |

U38A |

U38A |

U38 |

U38 |

U38 |

U38B |

| Imperial |

| Vulcanized & Fastener Rating (PIW) |

800 |

900 |

1000 |

1000 |

1200 |

1250 |

1350 |

1800

|

| Nom. Carcass Gauge (in.) |

0.340 |

0.300 |

0.368 |

0.429 |

0.518 |

0.464 |

0.453 |

0.613

|

| Nom. Carcass Weight (lb./sq. ft.) |

1.96 |

1.88 |

2.18 |

2.47 |

2.89 |

2.75 |

2.84 |

3.84

|

| Approximate 1/32 in. Cover Weight

(lb./sq. ft.) |

0.19 |

0.19 |

0.19 |

0.19 |

0.19 |

0.19 |

0.19 |

0.19

|

| Elastic Modulus (PIW) |

88,000 |

62,500 |

90,000 |

110,000 |

132,000 |

112,500 |

93,800 |

125,100

|

| Step Length (in.)*** |

16 |

Finger |

18 |

16 |

16 |

18 |

Finger |

Finger

|

| Metric |

| Vulcanized & Fastener Rating (PIW) |

140 |

158 |

175 |

175 |

210 |

219 |

236 |

315

|

| Nom. Carcass Gauge (in.) |

8.6 |

7.6 |

9.3 |

10.9 |

13.2 |

11.79 |

11.5 |

15.6

|

| Nom. Carcass Weight (lb./sq. ft.) |

9.6 |

9.2 |

10.64 |

12.1 |

14.1 |

13.43 |

13.9 |

18.7

|

| Approximate 1/32 in. Cover Weight

(lb./sq. ft.) |

1.17 |

1.17 |

1.17 |

1.17 |

1.17 |

1.17 |

1.17 |

1.17

|

| Elastic Modulus (PIW) |

15,410 |

10,950 |

15,760 |

19,260 |

23,120 |

19,700 |

16,430 |

21,910

|

| Step Length (in.)*** |

410 |

Finger |

460 |

410 |

410 |

460 |

Finger |

Finger |

Plylon Plus® rated belt tension can exceed 100%, with a maximum of 150%, during starting and stopping conditions. Fastener size recommendation may vary due to cover thickness, pulley diameters and system tension. Consult your Sales Representative or fastener manufacturer. R-6 fasteners must be installed with stainless steel rivets when belt tensions exceed 800 PIW (140 kN/m) for best results.

*P/P = Poly/Poly and P/N = Poly/Nylon

**Average permanent elongation values at 100% of rated belt tension are based on ISO 9856 test procedure. Consult your Sales Representative or Distributor for elastic and total elongation calculations.

***Consult your Sales Representative for vulcanized splice design for 900/2, 1350/3 and 1800/4 constructions.

|

Plylon Plus® Load Support – Maximum Belt Width

|

Material Weight |

0-40 lb./cu. ft. (0-640 kg/cu. m) |

41-80 lb./cu. ft. (641-1280 kg/cu. m) |

81-120 lb./cu. ft. (1281-1920 kg/cu. m) |

Over 120 lb./cu. ft. (Over 1920 kg/cu. m) |

| PIW/Plies |

Trough Idlers |

20 deg |

35 deg |

45 deg |

20 deg |

35 deg |

45 deg |

20 deg |

35 deg |

45 deg |

20 deg |

35 deg |

45 deg |

| Inches |

| 220/2 |

|

48 |

42 |

36 |

48 |

36 |

36 |

42 |

36 |

30 |

36 |

30 |

NR |

| 250/2 |

|

54 |

48 |

48 |

48 |

42 |

36 |

42 |

42 |

30 |

36 |

30 |

NR

|

| 330/3 |

|

60 |

54 |

48 |

60 |

48 |

42 |

54 |

48 |

42 |

48 |

42 |

36

|

| 375/3 |

|

72 |

60 |

60 |

60 |

60 |

48 |

54 |

54 |

48 |

48 |

42 |

36

|

| 400/2 |

|

60 |

54 |

54 |

54 |

48 |

42 |

48 |

48 |

42 |

42 |

36 |

30

|

| 440/4 |

|

72 |

60 |

54 |

66 |

60 |

48 |

60 |

54 |

48 |

54 |

48 |

42

|

| 500/4 |

|

84 |

72 |

72 |

72 |

60 |

54 |

72 |

60 |

54 |

60 |

54 |

48

|

| 600/3 |

|

84 |

72 |

72 |

72 |

60 |

54 |

72 |

60 |

54 |

60 |

54 |

48

|

| 750/3 |

|

84 |

72 |

72 |

72 |

60 |

54 |

72 |

60 |

54 |

60 |

54 |

48

|

| 800/4 |

|

96 |

84 |

84 |

84 |

72 |

72 |

84 |

72 |

60 |

72 |

60 |

54

|

| 900/2 |

|

78 |

78 |

72 |

72 |

72 |

60 |

72 |

60 |

54 |

60 |

54 |

48

|

| 1000/4 |

|

96 |

84 |

84 |

84 |

72 |

72 |

84 |

72 |

60 |

72 |

60 |

54

|

| 1000/5 |

|

108 |

96 |

96 |

96 |

84 |

84 |

96 |

84 |

72 |

84 |

72 |

72

|

| 1200/6 |

|

116 |

108 |

108 |

108 |

96 |

96 |

108 |

96 |

84 |

96 |

84 |

84

|

| 1250/5 |

|

116 |

108 |

108 |

108 |

96 |

96 |

108 |

96 |

84 |

96 |

84 |

78

|

| 1350/3 |

|

96 |

96 |

84 |

96 |

96 |

84 |

96 |

84 |

72 |

96 |

84 |

72

|

| 1800/4 |

|

118 |

118 |

108 |

118 |

118 |

108 |

108 |

108 |

96 |

108 |

96 |

84

|

| Millimeters |

| 220/2 |

|

1220 |

1070 |

910 |

1220 |

910 |

910 |

1070 |

910 |

760 |

910 |

760 |

NR

|

| 250/2 |

|

1370 |

1220 |

1220 |

1220 |

1070 |

910 |

1070 |

1070 |

760 |

910 |

760 |

NR

|

| 330/3 |

|

1520 |

1370 |

1220 |

1520 |

1220 |

1070 |

1370 |

1220 |

1070 |

1220 |

1070 |

910

|

| 375/3 |

|

1830 |

1520 |

1520 |

1520 |

1520 |

1220 |

1370 |

1370 |

1220 |

1220 |

1070 |

910

|

| 400/2 |

|

1520 |

1370 |

1370 |

1370 |

1220 |

1070 |

1220 |

1220 |

1070 |

1070 |

910 |

760

|

| 440/4 |

|

1830 |

1520 |

1370 |

1680 |

1520 |

1220 |

1520 |

1370 |

1220 |

1370 |

1220 |

1070

|

| 500/4 |

|

2130 |

1830 |

1830 |

1830 |

1520 |

1370 |

1830 |

1520 |

1370 |

1520 |

1370 |

1220

|

| 600/3 |

|

2130 |

1830 |

1830 |

1830 |

1520 |

1370 |

1830 |

1520 |

1370 |

1520 |

1370 |

1220

|

| 750/3 |

|

2130 |

1830 |

1830 |

1830 |

1520 |

1370 |

1830 |

1520 |

1370 |

1520 |

1370 |

1220

|

| 800/4 |

|

2440 |

2130 |

2130 |

2130 |

1830 |

1830 |

2130 |

1830 |

1520 |

1830 |

1520 |

1370

|

| 900/2 |

|

1980 |

1980 |

1830 |

1830 |

1830 |

1520 |

1830 |

1520 |

1370 |

1520 |

1370 |

1220

|

| 1000/4 |

|

2440 |

2130 |

2130 |

2130 |

1830 |

1830 |

2130 |

1830 |

1520 |

1830 |

1520 |

1370

|

| 1000/5 |

|

2740 |

2440 |

2440 |

2440 |

2130 |

2130 |

2440 |

2130 |

1830 |

2130 |

1830 |

1830

|

| 1200/6 |

|

2950 |

2740 |

2740 |

2740 |

2440 |

2440 |

2740 |

2440 |

2130 |

2440 |

2130 |

2130

|

| 1250/5 |

|

2950 |

2740 |

2740 |

2740 |

2440 |

2440 |

2740 |

2440 |

2130 |

2440 |

2130 |

1980

|

| 1350/3 |

|

2440 |

2440 |

2130 |

2440 |

2440 |

2130 |

2440 |

2130 |

1830 |

2440 |

2130 |

1830

|

| 1800/4 |

|

3000 |

3000 |

2740 |

3000 |

3000 |

2740 |

2740 |

2740 |

2440 |

2740 |

2440 |

2130 |

|

Plylon Plus® Troughability

Minimum Belt Width Table based on ISO 703 Testing Procedure

| Idlers |

220/2 |

250/2 |

330/3 |

375/3 |

400/2 |

440/4 |

500/4 |

600/3 |

750/3 |

800/4 |

900/2 |

1000/4 |

1000/5 |

1200/6 |

1250/5 |

1350/3 |

1800/4

|

| Inches |

| 20 Degree |

18 |

18 |

18 |

20 |

18 |

24 |

24 |

24 |

24 |

30 |

24 |

30 |

36 |

42 |

36 |

30 |

36

|

| 35 Degree |

18 |

18 |

24 |

24 |

24 |

30 |

30 |

30 |

30 |

36 |

30 |

36 |

42 |

48 |

42 |

36 |

42

|

| 45 Degree |

24 |

24 |

30 |

30 |

30 |

36 |

36 |

36 |

36 |

42 |

36 |

42 |

48 |

54 |

48 |

42 |

48

|

| Millimeters |

| 20 Degree |

460 |

460 |

460 |

510 |

460 |

610 |

610 |

610 |

610 |

760 |

610 |

760 |

910 |

1070 |

910 |

760 |

910

|

| 35 Degree |

460 |

460 |

610 |

610 |

610 |

760 |

760 |

760 |

760 |

910 |

760 |

910 |

1070 |

1220 |

1070 |

910 |

1070

|

| 45 Degree | 610 | 610 | 760 | 760 | 760 | 910 | 910 | 910 | 910 | 1070 | 910 | 1070 | 1220 | 1370 | 1220 | 1070 | 1220 |

If top cover and pulley cover are balanced (i.e., 3/16 in.x3/16 in. or 5mm x 5mm) or less than 1/16 in. (2mm) differential (i.e., 3/16 in.x5/32 in. or 4mm x 3mm), add 6 in. (150mm) to the minimum belt width. 6 in. (150mm). Narrower widths are possible if the belt is broken in for an extended period of time fully loaded. Consult your Sales Representative. Additional break-in time is required when the belt has been stored prior to installation in ambient temperatures of less than 50°F (10°C).

The above tables are based on top cover gauge equal or greater than the bottom (pulley) cover gauge.

|

Plylon Plus® Minimum Pulley Diameters

Minimum Belt Width Table based on ISO 703 Testing Procedure

|

Plylon Plus 220/2 |

Plylon Plus 250/2 |

Plylon Plus 330/3 |

Plylon Plus 375/3 |

Plylon Plus 400/2 |

Plylon Plus 440/4 |

Plylon Plus 500/4 |

Plylon Plus 600/3 |

Plylon Plus 750/3 |

Plylon Plus 800/4 |

Plylon Plus 900/2 |

| # of Plies |

2 |

2 |

3 |

3 |

2 |

4 |

4 |

3 |

3 |

4 |

2 |

| Inches |

| Over 80% Tension |

16 |

16 |

18 |

18 |

16 |

24 |

24 |

24 |

30 |

30 |

30

|

| 60% to 80% Tension |

14 |

14 |

16 |

16 |

14 |

20 |

20 |

20 |

24 |

24 |

24

|

| 40% to 60% Tension |

10 |

12 |

14 |

14 |

12 |

16 |

18 |

18 |

20 |

20 |

24

|

| Up to 40% Tension |

10 |

12 |

14 |

14 |

10 |

16 |

18 |

16 |

18 |

18 |

20

|

| Tails and Snubs |

10 |

12 |

14 |

14 |

10 |

16 |

18 |

16 |

18 |

18 |

20

|

| Millimeters |

| Over 80% Tension |

410 |

410 |

460 |

460 |

410 |

610 |

610 |

610 |

760 |

760 |

760

|

| 60% to 80% Tension |

360 |

360 |

410 |

410 |

360 |

510 |

510 |

510 |

610 |

610 |

610

|

| 40% to 60% Tension |

250 |

300 |

300 |

360 |

300 |

410 |

460 |

460 |

510 |

510 |

610

|

| Up to 40% Tension |

250 |

300 |

300 |

360 |

250 |

410 |

460 |

410 |

460 |

460 |

510

|

| Tails and Snubs | 250 | 300 | 300 | 360 | 250 | 410 | 460 | 410 | 460 | 460 | 510 |

Plylon Plus® HT belts (2/900, 3/1350, 4/1800) require a minimum pulley cover gauge of 1/8 in. (3.18mm) if vulcanized splicing will be used.

Plylon Plus® Minimum Pulley Diameters

|

Plylon Plus 1000/4 |

Plylon Plus 1000/5 |

Plylon Plus 1200/6 |

Plylon Plus 1250/5 |

Plylon Plus 1350/3 |

Plylon Plus 1800/4 |

| # of Plies |

4 |

5 |

6 |

5 |

3 |

4 |

| Inches |

| Over 80% Tension |

36 |

36 |

42 |

42 |

36 |

42

|

| 60% to 80% Tension |

30 |

30 |

36 |

36 |

30 |

36

|

| 40% to 60% Tension |

24 |

24 |

30 |

30 |

30 |

36

|

| Up to 40% Tension |

20 |

20 |

30 |

24 |

24 |

30

|

| Tails and Snubs |

20 |

20 |

30 |

24 |

24 |

30

|

| Millimeters |

| Over 80% Tension |

910 |

910 |

1070 |

1070 |

910 |

1070

|

| 60% to 80% Tension |

760 |

760 |

910 |

910 |

760 |

910

|

| 40% to 60% Tension |

610 |

610 |

760 |

760 |

760 |

910

|

| Up to 40% Tension |

510 |

510 |

760 |

610 |

610 |

760

|

| Tails and Snubs | 510 | 510 | 760 | 610 | 610 | 760 |

|

|