Syncrochain Belts

Quote Cart: 0 item(s) | View Quote Cart

|

|||||||||||||

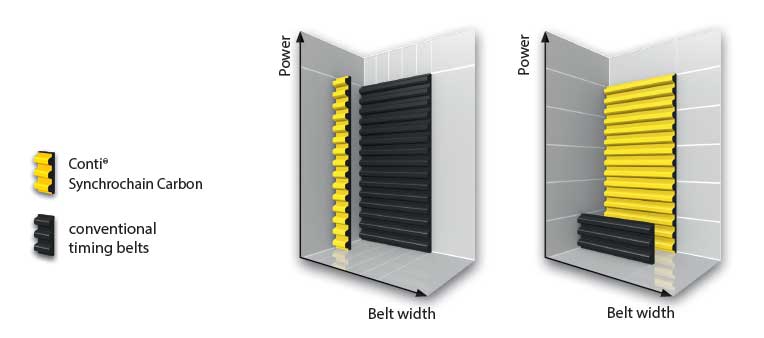

CONTI® SYNCHROCHAIN CARBONCarbon makes the difference! Higher power capacity, longer service lives and hardly any initial tension loss. With a newly developed carbon tension member at its heart, Conti® Synchrochain Carbon is launching itself into the leading position among the world’s highest-performance timing belts. Conti® Synchrochain CarbonIntelligent Design for Maximum Output.Light but durable polyurethane for teeth and backing. High-tensile and, at the same time, longitudinally stable carbon for the tension member. Plus a specially coated, wear-resistant face fabric. The intelligent design in combination with especially high-quality materials, is a defining features of Conti® Synchrochain Carbon. It ensures clean, smooth and particularly reliable power transmission both at high torques or dynamic loads.

The newly developed CTD profile (CTD: Conti Torque Drive) is the symbiosis of the HTD and the STD profile and combines the advantages of both in a single profile. The arch-shaped pulleyentry geometry, on the one hand, and the higher tooth, on the other, provide harmonic tooth meshing and therefore ultra smooth running. At the same time, it provides excellent protection against belt slip at high torque. Inside tensioning pulleysInside tensioning pulleys are to be preferred to outside tensioning pulleys as they do not cause any unfavorable alternate bending. The inside tensioning pulley is invariably toothed and is to be positioned on the slack side as close as possible to the large pulley, so as not to unnecessarily reduce the arc of contact on the small pulley. The number of teeth of an inside tensioning pulley should at least equal the smallest possible section-related number of teeth. Plain inside tensioning pulleys may be used when the outside diameter < 2.5 – 3.0 times larger than the smallest permissible number of teeth of the selected section. Outside tensioning pulleyOutside tensioning pulleys cause the drive belt to counterflex with an increase in the number of meshing teeth. The diameter of plain outside tensioning pulleys should be at least 1.5 times the diameter of the smallest pulley. Outside tensioning pulleys should in principle be positioned close to the small pulley. |

|||||||||||||

|

|

||||||||||||

|

|

||||||||||||

Add to Quote Cart

Applications

Syncrochain Belts is used in industrial transfer, handling, and support operations where reliable product performance and practical sourcing support are required.

Materials Overview

Material selection varies by media, environment, fitting interface, and service conditions. Existing product details above remain the primary source for specifications.

Selection Guidance

Match product configuration to your operating media, routing constraints, connection standards, and maintenance expectations. Use the quote cart to submit project requirements.

Installation and Maintenance Notes

Follow manufacturer handling practices, inspect components before installation, verify connection compatibility, and schedule routine inspections based on your service cycle.

Industries Served

Industrial manufacturing, processing, utilities, construction, transportation, and maintenance operations.

Technical Specifications

| Existing Technical Claim (Verbatim) |

|---|

| 50% lower compared with aramid. |

| 67°F to +176°F (-55°C to +80°C). |

| 40°F, please contact ContiTech) Suitable for tropical climates Resistant to aging and ozone Withstands |

| 22 28 min pitch diameter of the small toothed pulley dw [mm] 56. |

Related Products

- Super Swivel

- Super Torque Pd® Belts

- Survivor Hose Compound

- T-Bolt Clamps

- Teflon Hose

- Tetraglas Welding Cloth

FAQ

- How do I select the right Syncrochain Belts?

- Selection depends on your operating conditions, media, fittings, routing, and service goals. Submit a quote request for application-specific guidance.

- Can I request custom options for Syncrochain Belts?

- Custom manufacturing and configuration support are available on request. Include project details with your quote cart submission.

- Do you provide volume pricing?

- Bulk and volume pricing are available upon request. Add required quantities to the quote cart for review.

- How quickly can I receive a quote?

- Our team provides fast quote turnaround for standard and custom industrial product requests.

Trust and Support

- Fast quote turnaround

- Custom manufacturing available

- Bulk and volume pricing upon request

- Sales engineer assistance